Next generation of energetic materials to be developed at Virginia Tech

The Department of Defense has awarded the university $3 million to research new additive manufacturing processes to develop safer and more efficient energetic materials.

Virginia Tech has established itself as a global leader in additive manufacturing, as students are utilizing 3D printing technologies to rapidly produce parts and prototypes and a number of research groups are making ground-breaking discoveries in the manufacturing of metals.

The list of capabilities, innovations, and research opportunities in additive manufacturing at the university continues to explode. Now, the university can add smart energetics to that list.

Virginia Tech has been awarded $3 million from the Department of Defense to support the development of the next generation of energetic materials. Energetic materials include propellants, explosives, fuels, pyrotechnics, and reactive materials that are used in rocket motors, warheads, and munitions. Applying new techniques and processes used in additive manufacturing, researchers aim to create safe and smart energetic materials, with improved performance.

“Virginia Tech is in a unique position to support the Department of Defense in emerging energetic material technology as well as developing the next generation workforce,” said Greg Young, associate professor in the Kevin T. Crofton Department of Aerospace and Ocean Engineering and primary investigator on the project. “By assembling a team of experts in propulsion, energetics, and novel materials from across the university, we have the opportunity to both advance this new technology and make a positive impact on production processes right here in the New River Valley.”

Impact on Southwest Virginia and beyond

Expanding its reach beyond the Blacksburg campus, the project will partner locally with the Radford Army Ammunition Plant (RFAAP). The 4,300-acre government-owned, contractor-operated facility is just 5 miles from the Blacksburg campus and employs approximately 1,200 people. It is a primary propellant manufacturing facility for the U.S. military. Providing valuable guidance and input, the plant will identify its workforce needs, manufacturing and infrastructure gaps, and offer insight on the technical nature of the challenges in its processes.

The integration of the university's technical expertise and research capabilities with the Department of Defense production facilities presents a significant opportunity for the Southwest Virginia region to establish itself as a center for innovation and development in energetic materials.

“Virginia Tech’s world-class engineering research program, along with the capabilities of the Radford Army Ammunition Plant, means the 9th District is home to some of the best resources for innovation and development of energetic materials,” said Congressman Morgan Griffith. “I am pleased to have assisted in procuring this funding for Virginia Tech, as their work in this field will help strengthen our national security and support economic development in the region.”

“BAE Systems, operating contractor of the Radford Army Ammunition Plant, is committed to modernization to meet the Army’s current and future needs,” said Kelly Moran, research and development manager. “Through this collaboration with Virginia Tech, we continue to support the next generation of scientists in the New River Valley to carry on our mission to produce safer, more efficient energetic materials.”

Manufacturing of energetics

Today's energetic systems are predominantly fabricated using materials, manufacturing processes, and equipment that have not evolved significantly since World War II. Reliance on outdated methodologies not only limits efficiency and scalability, but also caps the potential advancements in the field.

Even with the same precursor materials, modern manufacturing techniques based on 3D printing present opportunities to enhance the performance and safety characteristics of energetic materials while potentially reducing development costs. Beyond improvements in existing materials, emerging 3D printing processes offer the possibility of on-site manufacturing of energetic materials with "dial-a-yield" type behavior. These advancements would enable both civilian and military users to fine-tune material performance according to immediate and changing needs on the ground, resulting in more adaptable and efficient applications of these materials.

As part of the grant, Virginia Tech will help the Radford Army Ammunition Plant test new manufacturing and evaluation technologies – without disrupting assembly lines – and incorporate new equipment into its production processes.

Virginia Tech partners

The research brings together a powerhouse group of experts from across the College of Engineering and unites facilities and capabilities ranging from synthesis to manufacturing, characterization, modeling, and design of additive manufactured materials. The team of faculty experts includes

- Greg Young, a leading expert in energetic materials, combustion, and propulsion and director of the Propulsion and Energetics Lab.

- Christopher Williams, whose expertise spans innovations in processes and materials, design methodologies, and cyber-physical security for additive manufacturing. He is director of the trailblazing Design, Research, and Education for Additive Manufacturing Systems (DREAMS) Laboratory.

- Michael Bortner, director of the Polymer Composite and Materials Lab, which provides extensive expertise in rheological behavior of materials to guide advanced manufacturing and process design for energetic materials.

- Eric Jacques, director of the Shock Tube Research Laboratory, whose expertise is on structural engineering, energetic materials, and large-scale blast experimentation.

Focus on experiential learning

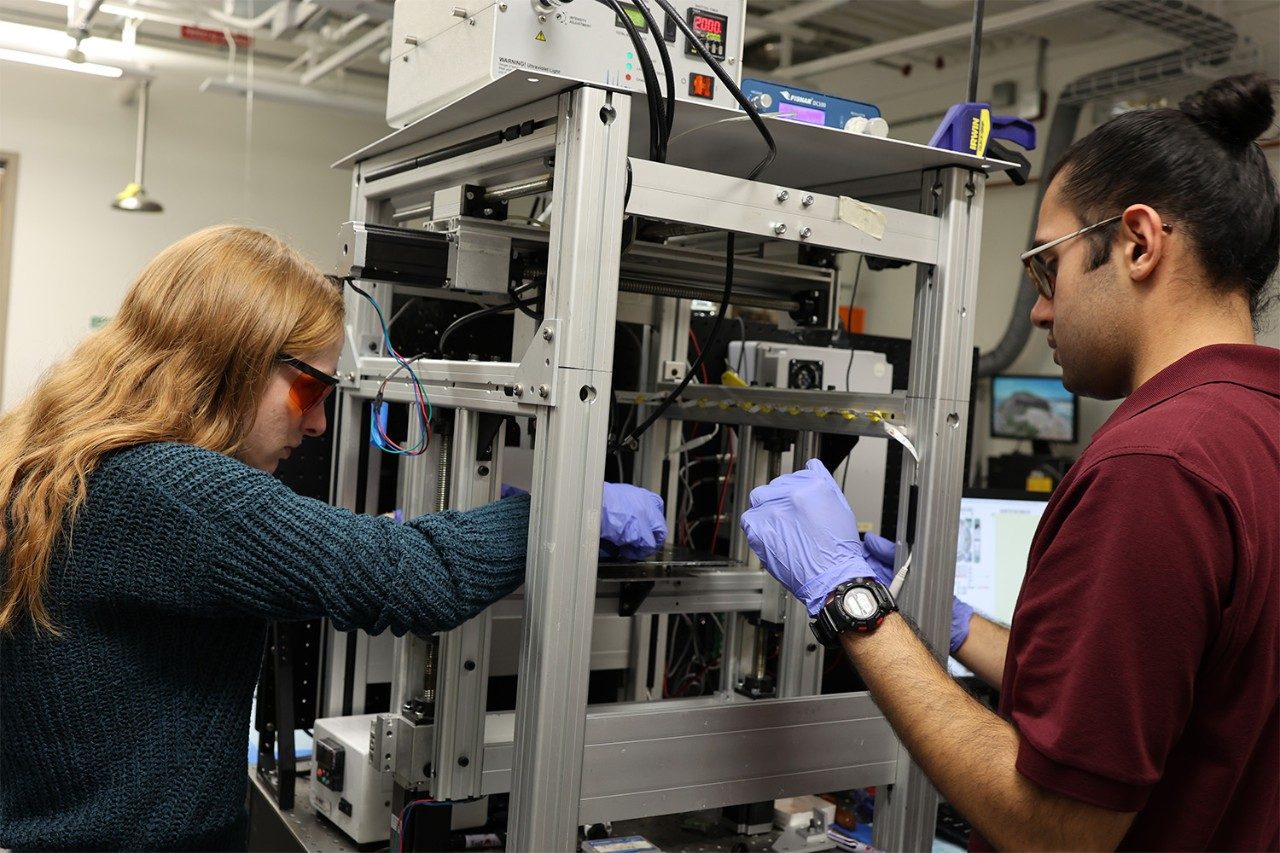

The research project also provides an opportunity to train the future workforce in addition to bridging educational experiences with the outside community. For the benefit of the students, the hands-on learning environment incorporates advanced diagnostics and state-of-the-art tests to develop smart energetics with customizable, optimized performance. For the benefit of the current workforce, the project aims to establish continuing education opportunities, ensuring that industry professionals stay current with the latest research and development for advanced manufacturing of energetic materials.

“We want to educate our students on how to do dangerous things safely,” said Young. “At the same time, by focusing on topics relevant to the plant’s needs and interests, we can accelerate workforce development to benefit the RFAAP and Southwest Virginia.”