Beauty meets function: Students revive ancient cooling technology for modern application

White porcelain structures, varying in shape and texture, lined a table in the College of Architecture, Arts, and Design research demonstration facility on Inventive Lane in Blacksburg. Many of them will be included in a ceramics exhibition in Richmond before returning to Blacksburg to undergo further study.

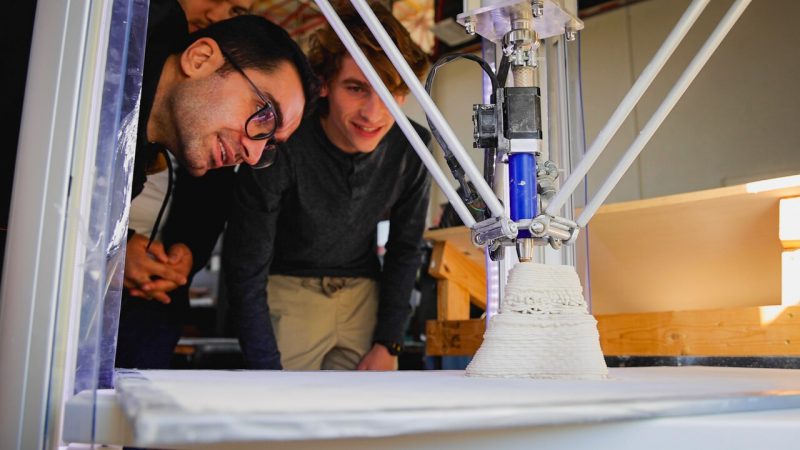

These aesthetically impressive pieces are more than visual art. They represent the potential revival of ancient approaches to cooling. Each 3D-printed structure, a reimagined and miniature version of an old-world design, is filled with sand and then water. Water seeps from inside the outer shell of each column. As the water turns to vapor, the heat is absorbed and dispersed from the column, thereby cooling the air surrounding it.

“Ancient Persia and Egypt used this. We saw that the ancient Chinese used this technology. Having this come back is kind of enchanting because it’s something people developed thousands of years ago, but using it now could lower carbon dioxide emissions,” said Ilan Farahi, an undergraduate student in industrial design and member of the Evaporative Cooling Partitions Project.

Farahi and other undergraduate and graduate students from industrial design and architecture spent the fall semester working with Brook Kennedy, associate professor in the School of Design, and Stefan AI, associate professor in the School of Architecture, on the project that explores sustainable solutions to rising temperatures. Using a computational design software program, the group designed the structures and then printed them.

“The program uses code that translates into 3D, so that’s how we are able to get more complicated shapes with more complex surface textures that contribute further to the evaporative cooling processes,” said Kennedy.

“3D printing offers various advantages in terms of speed, efficiency, design flexibility, and thermal resistance,” said Mohamed Ali, a graduate student in architecture. “I think we have gained a lot of experience working on this project.”

Partnering with professor Georg Reichard from the Myers-Lawson School of Construction, the group used infrared photography and video to measure the temperature difference between the surrounding air and the objects themselves as the water evaporated.

“We’ve learned a thing or two about materiality and how to optimize not only the surface texture of these objects through these tests, but we’ve also had rich discussions about materiality and how to amplify the evaporative process,” says Kennedy.

Looking to the past for design inspiration is an area of research that informed this project and Kennedy’s latest book, “Reimagining Alternative Technology for Design in the 21st Century.”

“We’ve gotten to a point in time and history where we are realizing the impacts human beings are having on the planet, and we’re really using all the tools available to try to see how to address certain critical global problems, whether that’s rising temperatures, questions of pollution, sustainability, or energy use and carbon emissions,” said Kennedy. “We’re researching forgotten technologies that have been effective years in the past before we had so much energy to use, and we’re asking, ‘Can we build using these technologies again for everybody’s benefit?’”

For architecture graduate student Saeed Sakhdari, exploring these questions through this experiential learning project and others has given him hands-on experience that he feels will elevate his portfolio.

“Lots of firms hire people who are focusing on energy, so it will be great having those projects in your portfolio and experience working with cutting-edge technology and new tools. All the firms are hiring people who have that knowledge,” said Sakhdari.

At this first phase of a multistage testing process, Kennedy said they are encouraged by how well the prototypes seem to be working, but there are additional steps to take, such as testing in a humidity chamber and a space to see how they perform with people.

The project operates on funding provided by the Institute for Creativity, Arts, and Technology and the Center for Future Work Places and Practices, but Kennedy and Al would eventually like to seek external funding for larger scale development. Collectively, they see a lot of promise and want to carry the project as far as possible.

“It’s understandable that there would be some skepticism about how to take on the rather challenging task of cooling buildings without using energy. But at the same time, one of the points of research is to ask questions maybe the building and construction industry wouldn’t ask, or ask questions that we’re afraid to ask, and be willing to be wrong. That’s what research is about, taking chances, asking big world questions, and seeing where it goes,” said Kennedy. “We’re keeping our eyes open and our critical minds engaged.”

.jpg.transform/m-medium/image.jpg)