Instrumentation expands capabilities at Center for Research and Engineering in Aero/Hydrodynamic Technology

A new high-speed camera system is part of a second phase in building optical flow measurement capabilities at the Stability Wind Tunnel, Advanced Propulsion and Power Laboratory, and Cavitation, Propulsion and Multiphase Flow Laboratory.

Understanding the behavior of flow and flow acoustics — be it underwater or in the air — is crucial to designing and building quieter, faster, and more energy-efficient vehicles for sea and sky.

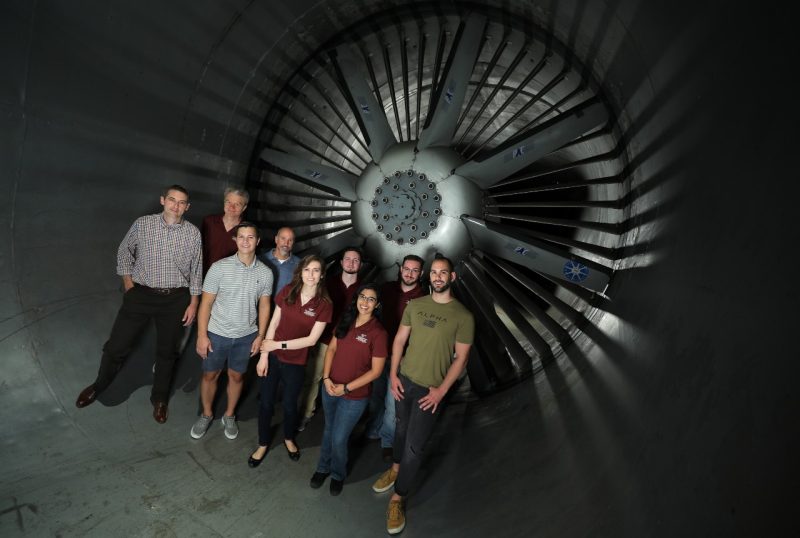

A number of Virginia Tech engineering facilities dedicate their resources to research and education relevant to flow and flow acoustics. Due to the university’s proximity to several naval laboratories in the mid-Atlantic region, Virginia Tech has long been committed to building and sustaining research with direct relevance to the U.S. Navy and investing in instrumentation that will push research capabilities ahead of the curve.

For a leading research institution collaborating with the Navy, it also is vital to develop a pipeline of trained engineers who will enter the workforce and support the Department of Defense mission.

Virginia Tech was recently awarded $391,000 through the Department of Defense’s Defense University Research Instrumentation Program (DURIP). The grant supports the purchase of additional research cameras and hardware for high-speed flow and flow acoustic measurement at the Stability Wind Tunnel, the Advanced Propulsion and Power Laboratory, and the Cavitation, Propulsion and Multiphase Flow Laboratory.

The flexibility of the new equipment to be shared and utilized at all three facilities will ensure that large numbers of students can be trained in the use of this cutting-edge technology.

The highly competitive award is the result of a merit competition for DURIP funding conducted by the Army Research Office, Office of Naval Research, and Air Force Office of Scientific Research.

Let’s talk about flow

Fluid flows are classified as either laminar or turbulent, and their behaviors are drastically different. Laminar flows are smooth and streamlined, whereas turbulent flows are irregular and chaotic.

For example, when a turbulent flow buffets against the hull of the fuselage on a plane, the force causes vibrations, resulting in noise inside the cabin. For accurate fluid modeling in computational fluid dynamics, engineers and designers need to have a deep and full understanding of these turbulent motions.

“Our vision is to measure everything, everywhere, every time,” said William Devenport, the Crofton Professor in Engineering and director of the Virginia Tech Stability Wind Tunnel. “For the kinds of problems our team is tackling — pressure fluctuations in boundary layers, sounds made by a rotor cutting through turbulence, or cavitation — there are complex hidden properties of flow and flow acoustics that we need to seek out.”

The new high-speed camera system is part of a second phase in building optical flow measurement capabilities that fully leverage the internationally recognized facilities. In 2018, as part of an earlier DURIP award, researchers purchased a planar particle imaging velocimetry system to conduct whole-plane flow-field measurements at an unprecedented full-resolution rate of 25,600 frames per second. During experiments, researchers can add particles, shine a laser sheet through the flow, and capture the results on high-speed video. By comparing each frame, the team can see how the particles move and behave and can determine the velocity, flow speed, and direction.

Adding two new high-speed cameras and software expands the system’s measurement capabilities to provide a 3D view, thus capturing a more advanced level of flow measurement resolution and particle tracking processing. Seeing the flow in 3D is key to understanding why it behaves the way it does because the turbulence moves and interacts in 3D.

High-speed computer hardware and software systems will increase measurement efficiency, allowing researchers to acquire statistically converged data in a much shorter time than conventional measurements. This feature is critical because measurement efficiency is a major productivity multiplier in fundamental flow and flow acoustics research.

Boosting ongoing and future research

“While there are similar systems like ours at other research facilities, our application of the instrumentation, specifically in the Stability Wind Tunnel, positions us ahead of the curve,” said Devenport. “Utilizing this new system in an acoustic wind tunnel, in combination with the facility’s existing unique capabilities, enables us to look at flow and flow acoustics in unprecedented ways.”

The enhanced capabilities will directly impact a number of ongoing and proposed Office of Naval Research-sponsored research projects.

- Devenport and Professor Todd Lowe are co-investigating a project on the form and source of pressure fluctuations made by turbulence near the hull or fuselage of a vehicle. To mathematically visualize the source of these pressures requires simultaneous measurement of the flow velocities everywhere in a volume of the flow as a function of time. The new equipment will make this possible for the first time, and it will be used in concert with the Stability Wind Tunnel’s groundbreaking resonating sensor array. Understanding the details and origin of these pressure fluctuations will improve the accuracy with which flow-induced fuselage or hull vibration can be predicted, allowing for the development of airplanes with reduced cabin noise.

- Devenport and Assistant Professor W. Nathan Alexander are researching the aeroacoustic response of turbulence ingesting rotor systems. When propellers on an airplane or an unmanned autonomous vehicle ingest turbulence, they make noise that can be radically modified during takeoff and landings. The 2D particle tracking velocimetry (PTV) system will be used to visualize the details of transient disturbances as they are sucked into a propeller. Simultaneously, the team will measure the sound radiated by the rotor using an array of 251 microphones. Understanding both will help directly identify the components of the turbulence responsible for the loudest noises, and provide designers the information they need to design quieter vehicles.

- In the Cavitation, Propulsion, and Multiphase Flow Laboratory, Professor Olivier Coutier-Delgosha is investigating cavitation, or the vaporization of water, in propellers or appendices of high-speed ships and how it affects increasing speed and limitations on propeller efficiency. The new PTV system will be combined with fast X-ray imaging at 270,000 hertz and a space resolution of 1 micrometer, to resolve the time evolution of all cavitation bubbles. The high-speed data captured will enable the team to visualize how the perturbations coming from the hull wake and the surface roughness impact the flow field on propeller blades or on rudders as well as the flow instabilities generated by cavitation.

Each of these research projects falls under the Center for Research and Engineering in Aero/Hydrodynamic Technology and the Kevin T. Crofton Department of Aerospace and Ocean Engineering.

Educational pipeline

“Research training for graduate students is of critical interest to the Navy and the Department of Defense,” said Devenport. “Through the students’ experience in participating in this type of research, they are poised to be leaders and innovators once they enter the workforce. The Navy sees value in development of the pipeline and is committed to invest in educational research to see it flourish.”

Graduate students involved in research projects using this new measurement system will learn essential skills in the operation of high-speed, high-resolution optical diagnostic techniques, along with the associated data processing, thus expanding their understanding of flow physics under a variety of conditions.

In addition, the Stability Wind Tunnel is dedicated to introducing undergraduate students to the latest techniques and a realistic large-scale facility testing environment by hosting undergraduate laboratory experiments through courses in the aerospace and ocean engineering and mechanical engineering departments. These experiments typically coincide with sponsored research projects to expose undergraduates to the scale of such a project while also directly contributing to the research effort.