Porous carbon fiber research one step closer to use in automotive industry

An update on recently reported research on porous carbon fibers shows how this material can be used in an industrial setting, marking an important step from the theoretical to application.

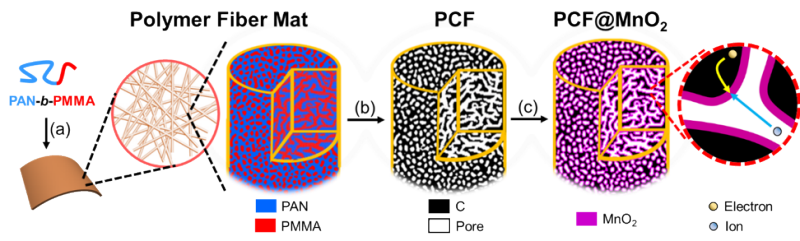

Guoliang “Greg” Liu, an assistant professor of chemistry in the College of Science and a member of the Macromolecules Innovation Institute, has been working on developing carbon fibers with uniform porous structures. In a journal article published recently in Science Advances, Liu detailed how his lab used block copolymers to create carbon fibers with mesopores uniformly scattered throughout, similar to a sponge.

Just one week after, Liu has published yet another article, this time in Nature Communications. The new article shows how Liu’s porous carbon fibers can enable high energy density and high electron/ion charging rates, which are typically mutually exclusive in electrochemical energy storage devices.

“This is the next step that will be relevant to industry,” Liu said. “We want to make an industrial-friendly process. Now industry should seriously look at carbon fiber not only as a structural material but also an energy storage platform for cars, aircrafts, and others.”

Introducing pseudocapacitive materials

Carbon fibers are already widely used in the aerospace and automotive industries because of their high performance in a variety of areas, including mechanical strength and weight. Liu’s long-term vision is to build exterior car shells out of porous carbon fibers that could store energy within the pores.

But carbon by itself isn’t sufficient. Although a structurally prime material, carbon doesn’t possess high enough energy density to create supercapacitors for highly demanding applications.

The current industry standard couples carbon with what’s known as pseudocapacitive materials, which unlock the ability to store a large amount of energy but induce another problem of slow charge-discharge rate.

A commonly used pseudocapacitive material is manganese oxide (MnO2) due to its low cost and reasonable performance. To load MnO2 onto carbon fiber or another material, Liu soaks the fibers in a solution of KMnO4 precursor. The precursor then reacts with carbon, etches away a thin layer of carbon, and anchors onto the rest of the carbon, creating a thin coat of about 2 nm in thickness.

But industry faces a challenge with MnO2. Too little MnO2 means the storage capacity is too low. Too much MnO2 creates too thick of a coat that is electrically insulating. And worse, it slows down the transport of ions. Both contribute to slow charge-discharge rates.

“We want to couple carbon with pseudocapacitive materials because they together have a much higher energy density than pure carbon. Now the question is how to solve the problem of electron and ion conductivity,” Liu said.

However, Liu has discovered that his porous carbon fibers can overcome this impasse. Tests in his lab showed the best of both worlds: high loading of MnO2 and sustained high charging and discharging rates.

Liu’s lab proved they could load up to 7 mg/cm2 of MnO2 before performance dropped. That’s double or nearly triple the amount of MnO2 that industry can currently utilize.

“We have achieved 84 percent of the theoretical limit of this material at a mass loading of 7 mg/cm2,” Liu said. “If you load 7 mg/cm2 of other materials, you will not reach this.”

Short-term applications

At the rate Liu’s lab is publishing results, cars powered by exterior shells could be here sooner than we think, but Liu pumps the brakes on that idea.

“In a long-term vision, we could replace gasoline with just electric supercapacitor cars,” Liu said. “At this moment, the minimum of what we could do is to utilize this as an energy storage part in cars.”

Liu said a shorter-term application could be utilizing the carbon fiber parts to deliver lots of energy in a short period to accelerate cars faster.

But Liu is also looking beyond the automotive industry into other transportation applications.

“If you want a drone to deliver products for Amazon, you want the drone to carry as much weight as possible, and you want the drone to be as lightweight as possible,” Liu said. “Carbon fiber-based drones can do both jobs. The carbon fibers are strong structural materials for carrying the goods, and they are energy storage materials to provide power for transportation.”

The research on this material is accelerating in Liu’s lab, and he said he still has many more ideas to test.

“What I believe is that porous carbon fibers are a platform material,” Liu said. “The first two papers, we focused on energy storage for vehicles. But we believe that this material can do more than that. Hopefully we’ll be able to tell more stories soon.”

The first author of the paper is Tianyu Liu, a postdoctoral associate in the Liu Lab. Also involved in the research were Zhengping Zhou and Yichen Guo, two former postdoctoral associates, and Dong Guo, a third-year doctoral student in the Department of Chemistry.

Read More