Student team debuts decadent, convenient banana dessert at New Orleans food expo

Who doesn’t like a banana split? Fresh fruit, three flavors of ice cream and chocolate syrup. Yum.

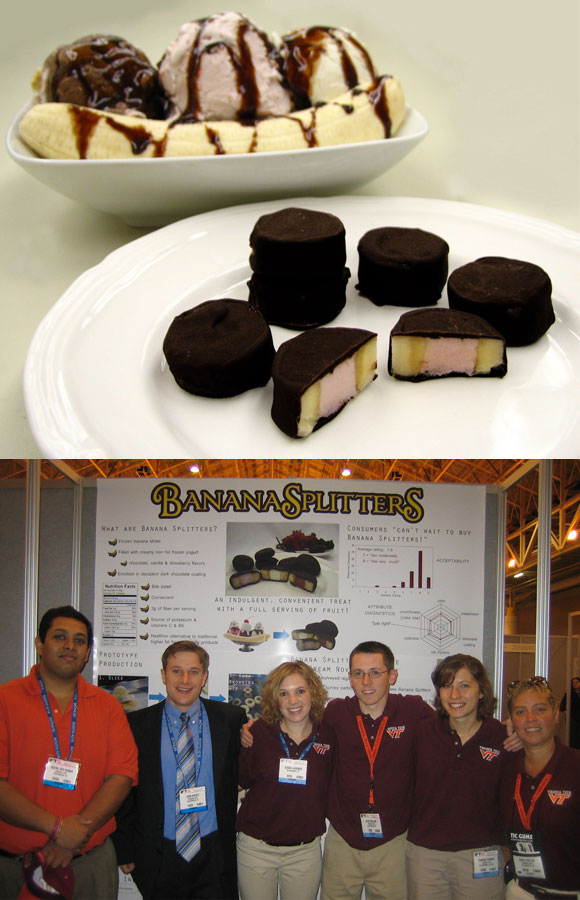

That vision was the subjective basis for a new product developed by a team of Virginia Tech students – frozen bite-sized slices of banana filled with creamy chocolate, vanilla, or strawberry non-fat frozen yogurt and enrobed in dark chocolate. Called “Banana Splitters,” the new confection is packaged as nine individual pieces – three of each flavor – in a sleeve, six sleeves in a package to be available next to the ice cream and other frozen goodies. And, get this, an entire sleeve is a serving.

The students say they would also like to see their award-winning decadent dessert available from fast-food restaurants, nine pieces to be packaged in a banana-shaped container.

The 13-member Virginia Tech Food Science and Technology Product Development Team created Banana Splitters as their entry in the Institute of Food Technologists (IFT) Product Development Competition, sponsored by Mars Inc., and was one of six finalist teams to receive a travel grant to the Institute of Food Technologists Annual Meeting and Food Expo in New Orleans in June.

“We wanted a product that would meet current market trend, including convenience, bite-sized pieces, and portion control,” said Sabrina Hannah of Elverson, Pa., a Ph.D. candidate in food science and technology in the College of Agriculture and Life Sciences. “We also wanted the product to stand out in the market, which is why we designed it to have a full serving of fruit per serving.”

"It seems that some people consider fiber, potassium, and antioxidants when they think about dessert." “We briefly considered slices of cream cheese packaged in an edible film,” said John Koontz of Falls Church, Va., a recent Ph.D. graduate in food science and technology. “But people spread different thicknesses of cream cheese on their bagels.”

Besides, the Banana Splitters were wildly popular in the students’ product development class, said Denise Gardner of Reading, Pa., a master’s degree student in food science and technology. “And we thought this was more fun,” she admits.

Persistently practical, Govindaraj Dev Kumar of Chennai, India, a master’s degree student in food science and technology, points out that each serving of the product has a full serving of fruit and that non-fat yogurt is a healthy alternative to ice cream. “The judges liked that there are two different ways to sell it,” he said.

A sensory panel liked the product too, giving it an average rating of 7.6 on a scale of nine. “That is between ‘likes moderately’ and ‘likes very much’,” said Annie Aigster of Valencia, Venezuela, a human nutrition, foods, and exercise Ph.D. candidate.

In addition to tests of popularity, the students did a number of other tests in preparing their product. They tested for safety and shelf life. Even though the individual packaging would make consumer abuse unlikely, they tested quality and safety of the product, including under thoughtless handling, such as handling the product without proper hand washing and leaving a container out for as long as 30 minutes then refreezing it. Banana Splitters demonstrated no significant safety concerns.

The team members prepared the product in pilot plant conditions using the food processing lab, dairy processing lab, and sensory kitchen of Virginia Tech’s Department of Food Science and Technology. They purchased the bananas locally, using color as an indicator of ripeness and selecting for size and shape. Following slicing and coring, they solved the issue of bananas’ tendency to brown with a solution of dextrose, ascorbic acid, and citric acid. The slices were then flash frozen and the frozen yogurt was piped into the centers of the slices.

There was discussion and some enjoyable testing to determine what kind of chocolate would be used – thick, thin; dark, milk. A product with the proper thickness was selected from commercial providers and a decision was made to go with the dark chocolate because it is currently popular.

The students also designed the scale up to a commercial manufacturer. Changes from the pilot-level process would include measuring sugar content to determine ripeness, for instance. And banana peels, size-rejected slices, and cores could be used in extracts and purees.

The team’s market study found that the delicious, convenient treat with a healthy twist appeals to people of all ages.

When the team sent their entry to the Institute of Food Technologists, they also sent the report to Virginia Tech Intellectual Properties Inc., which has applied for a patent on the students’ behalf.

Members of the team in addition to Aigster, Gardner, Hannah, Kumar, and Koontz, are food science and technology students Gerard Alcantara of Lorton, Va., a senior; Emma Buck of Columbus, Ohio, a Ph.D. candidate; Daniel Crum of Barnesville, Ohio, a senior; Rebecca Dain-Baker of Chesapeake, Va., a recent master’s degree graduate; Kevin Holland of Bradford, Pa., a Ph.D. candidate; Robert Moore of Floyd, Va., a master’s degree student; Katie Robbins of Syracuse, N.Y., a recent bachelor’s degree graduate; Julie McKinney of Radford, Va., a recent Ph.D. graduate; and Carla Tyler of Troy, N.Y., a master’s degree student. The team is advised by Sean O’Keefe, associate professor of food science and technology.

Wilbur Chocolate, Cargill Foods Company, and YoCream International Inc. donated products to the team for the Banana Splitters project.