Virginia Tech researcher’s breakthrough discovery uses engineered surfaces to shed heat

More boiling means faster cooling, and when it comes to cooling equipment like nuclear reactors, every degree counts.

Splash a few drops of water on a hot pan and if the pan is hot enough, the water will sizzle and the droplets of water seem to roll and float, hovering above the surface.

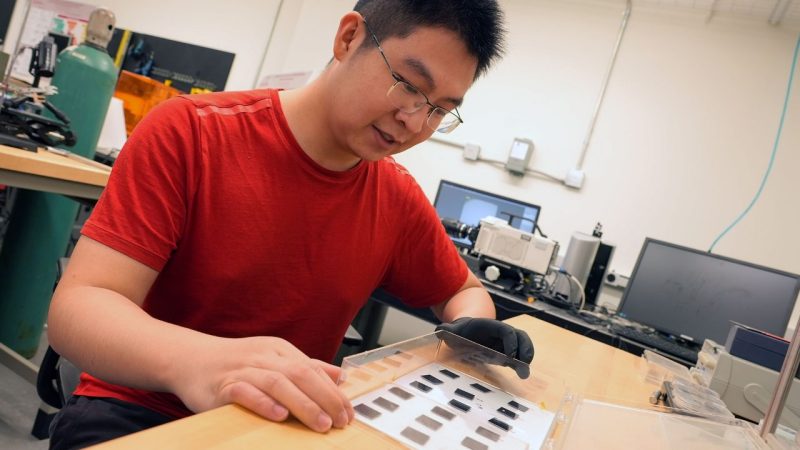

The temperature at which this phenomenon, called the Leidenfrost effect, occurs is predictable, usually happening above 230 degrees Celsius. The team of Jiangtao Cheng, associate professor in the Virginia Tech Department of Mechanical Engineering, has discovered a method to create the aquatic levitation at a much lower temperature, and the results have been published in Nature Physics. Alongside first author and Ph.D. student Wenge Huang, Cheng's team collaborated with Oak Ridge National Lab and Dalian University of Technology for sections of the research.

The discovery has great potential in heat transfer applications such as the cooling of industrial machines and surface fouling cleaning for heat exchangers. It also could help prevent damage and even disaster to nuclear machinery.

Currently, there are more than 90 licensed operable nuclear reactors in the U.S. that power tens of millions of homes, anchor local communities, and actually account for half of the country’s clean energy electricity production. It requires resources to stabilize and cool those reactors, and heat transfer is crucial for normal operations.

The physics of hovering water

For three centuries, the Leidenfrost effect has been a well-known phenomenon among physicists that establishes the temperature at which water droplets hover on a bed of their own vapor. While it has been widely documented to start at 230 degrees Celsius, Cheng and his team have pushed that limit much lower.

The effect occurs because there are two different states of water living together. If we could see the water at the droplet level, we would observe that all of a droplet doesn’t boil at the surface, only part of it. The heat vaporizes the bottom, but the energy doesn’t travel through the entire droplet. The liquid portion above the vapor is receiving less energy because much of it is used to boil the bottom. That liquid portion remains intact, and this is what we see floating on its own layer of vapor. This has been referred to since its discover in the 18th century as the Leidenfrost effect, named for German physician Johann Gottlob Leidenfrost.

That hot temperature is well above the 100 degree Celsius boiling point of water because the heat must be high enough to instantly form a vapor layer. Too low, and the droplets don’t hover. Too high, and the heat will vaporize the entire droplet.

New work at the surface

The traditional measurement of the Leidenfrost effect assumes that the heated surface is flat, which causes the heat to hit the water droplets uniformly. Working in the Virginia Tech Fluid Physics Lab, Cheng’s team has found a way to lower the starting point of the effect by producing a surface covered with micropillars.

“Like the papillae on a lotus leaf, micropillars do more than decorate the surface, said Cheng. “They give the surface new properties.”

The micropillars designed by Cheng’s team are 0.08 millimeters tall, roughly the same as the width of a human hair. They are arranged in a regular pattern of 0.12 millimeters apart. A droplet of water encompasses 100 or more of them. These tiny pillars press into a water droplet, releasing heat into the interior of the droplet and making it boil more quickly.

Compared to the traditional view that the Leidenfrost effect triggers at 230 degrees Celsius, the fin-array-like micropillars press more heat into the water than a flat surface. This causes microdroplets to levitate and jump off the surface within milliseconds at lower temperatures because the speed of boiling can be controlled by changing the height of the pillars.

Lowering the limits of Leidenfrost

When the textured surface was heated, the team discovered that the temperature at which the floating effect was achieved was significantly lower than that of a flat surface, starting at 130 degrees Celsius.

Not only is this a novel discovery for the understanding of the Leidenfrost effect, it is a twist on the limits previously imagined. A 2021 study from Emory University found that the properties of water actually caused the Leidenfrost effect to fail when the temperature of the heated surface lowers to 140 degrees. Using the micropillars created by Cheng’s team, the effect is sustainable even 10 degrees below that.

“We thought the micropillars would change the behaviors of this well-known phenomenon, but our results defied even our own imaginations,” said Cheng. “The observed bubble-droplet interactions are a big discovery for boiling heat transfer.”

The Leidenfrost effect is more than an intriguing phenomenon to watch, it is also a critical point in heat transfer. When water boils, it is most efficiently removing heat from a surface. In applications such as machine cooling, this means that adapting a hot surface to the textured approach presented by Cheng’s team gets heat out more quickly, lowering the possibility of damages caused when a machine gets too hot.

“Our research can prevent disasters such as vapor explosions, which pose significant threats to industrial heat transfer equipment,” said Huang. “Vapor explosions occur when vapor bubbles within a liquid rapidly expand due to the present of intense heat source nearby. One example of where this risk is particularly pertinent is in nuclear plants, where the surface structure of heat exchangers can influence vapor bubble growth and potentially trigger such explosions. Through our theoretical exploration in the paper, we investigate how surface structure affects the growth mode of vapor bubbles, providing valuable insights into controlling and mitigating the risk of vapor explosions.”

Another challenge addressed by the team is the impurities fluids leave behind in the textures of rough surfaces, posing challenges for self-cleaning. Under spray cleaning or rinsing conditions, neither conventional Leidenfrost nor cold droplets at room temperature can fully eliminate deposited particulates from surface roughness. Using Cheng’s strategy, the generation of vapor bubbles is able to dislodge those particles from surface roughness and suspend them in the droplet. This means that the boiling bubbles can both move heat and impurities away from the surface.