Class of 2023: Greg Hahn is doing big things - and printing them in 3D

Name: Greg Hahn

College: College of Engineering

Degree: Ph.D. in materials science and engineering

Dissertation: Additive Friction Stir Deposition of Aerospace Al-Zn-Mg-Cu-Zr Alloys: Leveraging Processing and Metallurgical Science for Structural Repair

Hometown: Virginia Beach, VA

Plans after graduation: Hahn will be joining Meld PrintWorks, a 3D printing start up in Christiansburg, VA.

Favorite Hokie memory: “My thesis defense in Goodwin this December, where I presented my results and findings publicly. It’s a little stressful–you either get your Ph.D. or you don’t–but it was nice to have my family and friends in one place, even though they glazed over when I talked about research!”

As an undergraduate at Virginia Tech, Greg Hahn wasn’t expecting to earn his doctorate in a field that 3D prints thousands of pounds of machinery. His plans got bigger as an upperclassmen, however, when he took a required course in materials science and engineering.

“I got into this my junior year of undergrad here. My mechanical behavior course was taught by my eventual graduate advisor, Hang Yu," Hahn recalled. "He was looking for students to join his research team, but I actually met with him to argue a test score—he gave me a 97 and I thought I deserved higher. Then he asked if I wanted to be part of his research group.”

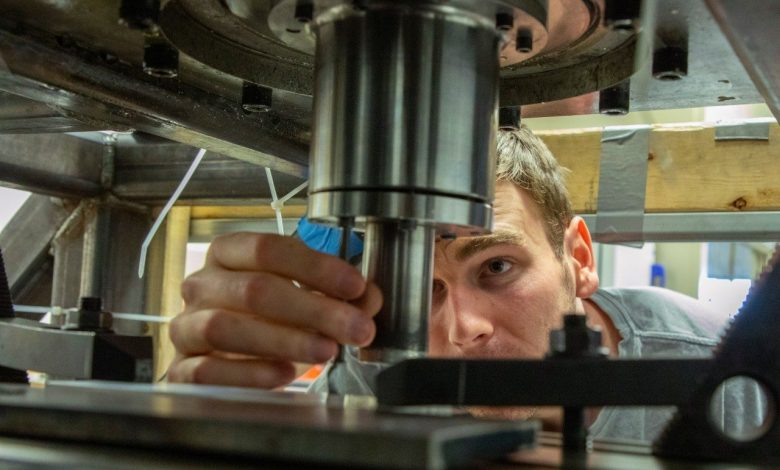

Fast forward several years, and Hahn found himself in a lab processing “weird materials” that could be deposited and used in the production of large-scale machinery parts. While most materials used in 3D printing melt, Hahn focuses on processing materials without melting, with the hopes of decreasing the cost and lead time of production, while creating more complex geometries.

“I make really big parts out of aluminum for going on airplanes, out of alloys that can’t undergo melt and solidification. The majority of materials used in aerostructures are produced by forging and are difficult to produce in small quantities,” Hahn explained. “Our process is looking to replace large forgings and castings. It doesn’t always sound that cool, but it’s really awesome when you’re a nerd like me and you realize how hard it is to make these parts through any processes, but especially reliably, which is what it’s all about.”

On printing’s cutting edge

Hahn was drawn to Virginia Tech for the opportunities he knew he couldn’t get elsewhere. Through coursework, research, and internships, such as his research assistant internship at a nanotube startup, he was able to hone his field of interest and make use of cutting edge technology.

“It was really cool to be accepted because Virginia Tech has the first AFSD 3D printer that was ever made. It’s the really bare bones model so I did my whole thesis on that research grade model, but now I’ll get to use the professional version, the one with the bells and whistles,” said Hahn.

Post graduation Hahn will be utilizing this industry-grade 3D printer when he joins Meld PrintWorks, a start up in Christiansburg, VA where Hahn has been working part time for the past months. In this next stage of his career, he will continue the research he was encouraged to freely pursue by Yu.

“Dr. Yu is very hands off and kind of requires his students to go do their own thing, and a lot of times he reels us back in to keep us grounded,” Hahn said. “It’s cool when your advisor doesn’t have to push you forward, but is more so keeping you in check.”

Although Hahn’s research path was unexpected, he quickly found his niche under the mentorship of Yu, and went on to acquire other crucial industry skills.

“Professor Yu manages student research projects in a way that allowed me to do project management work on top of my research so I feel really confident going into industry with four years of that in addition to my research.”

Hahn also attributes his engineering successes to his team oriented attitude. Between athletics and academics, his Virginia Tech experience has been about collaboration, and working with others towards a common goal.

“I played club volleyball for six or seven years here, and even played through my second year of grad school. I’m team oriented and that's always been helpful," Hahn said. "It’s just what I do.”

Collaboration will continue in Hahn’s career, as he goes on to bigger, and even bigger things. Recently, he met with a collaborator that used the world's largest 3D printer, and the parts coming out were larger than he was.

“I’m 3D printing things that are bigger than you are," Hahn said. "It's cool stuff. I can stand on my 3D printer and the parts are coming out bigger than me. Essentially I get to do a lot of research to advance the cutting edge of science.”