Virginia Tech is satisfying the craving for semiconductor advancement

Sometimes the burritos show up before the chips.

In the case of Virginia Tech’s major in chips-scale integration, 50 homemade breakfast burritos helped draw faculty to a Cinco de Mayo-themed meeting in 2016. Anchoring the agenda: a vote on a new curriculum for the Bradley Department of Electrical and Computer Engineering. The potential revamping, which included the new semiconductor-focused major and 13 others, would be the department’s first major curriculum shift since 1989, nearly three decades earlier.

That pivotal meeting took place six years before semiconductors, or chips as they are commonly called, and the critical hardware components’ manufacturing became a national focus. So universal buy-in for the new curriculum was far from a given.

“At one point during the meeting, Fred Lee stood up, and it goes totally quiet,” said Luke Lester, head of the department and co-creator of the new curriculum. “I remember thinking this is either going to be really good or really bad.”

A University Distinguished Professor Emeritus, Lee endorsed the new curriculum and capped the roughly two-month sprint of Lester and his colleagues to reimagine it in ways that better reflected real-world needs and more effectively communicated possibilities in the field to future students.

“I went ‘Hallelujah’ in my head,” Lester said.

The successful vote that day helped propel the chips-scale integration major into existence, and the effort was boosted by receiving a National Science Foundation Revolutionizing Engineering Departments grant just a few months later.

Since its inception, the chips-scale integration major has recorded a sevenfold increase in the number of students declaring and graduating with a specialization in chips and is among the factors that have positioned Virginia Tech to play a key role in the United States’ effort to onshore semiconductors today.

“Back then, we surely weren’t predicting the CHIPS and Science Act, but working with our advisory board and faculty, we were forecasting that this was needed and began encouraging more and more students toward the major,” Lester said. “We’re excited to be in this position now because our faculty and students not only get to be part of this national priority to become more globally competitive in the semiconductor space, they’re going to change the world and make other people’s lives better.”

Signed into federal law in August 2022, the term “CHIPS” in the CHIPS and Science Act stands for Creating Helpful Incentives to Produce Semiconductors, while “chips” also serves as a common term for semiconductors.

It’s true what they say about chips, you can’t just have one. In fact, about 1,500 of these critical hardware components are needed to successfully outfit a single automobile.

It’s also true that there isn’t just one Virginia Tech effort helping to find viable solutions to meet the growing demand for research, development, and manufacturing of chips in the United States. The land-grant university is leading in multiple ways, not only in classrooms and labs, but across the state, country, and even around the globe.

Faculty are advancing cutting-edge research ranging from examining semiconductors’ potential to help reduce greenhouse gas emissions to exploring the role of artificial intelligence in semiconductor configurations and efficiency. To help cultivate work-ready graduates, the researchers include students throughout the process.

This spring, Virginia Tech was named the anchor institution for the Virginia Alliance for Semiconductor Technology (VAST) and Virginia Tech’s Masoud Agah its founding director. Bringing together numerous higher education institutions, government entities, and industry partners, the initiative will create a statewide network to advance research, capitalize on economic opportunities, and cultivate a robust and diverse workforce.

This effort is bolstered by the university’s designation both as a founding member of the 21-institution, Micron-formed Northeast University Semiconductor Network and the 11-university network Upwards for the Future, which was designed to cultivate a more diverse and robust talent pipeline for the semiconductor workforce that spans the U.S. and Japan, this year.

And in July, just weeks shy of the CHIPS Act’s one-year anniversary, Virginia Tech hosted more than 100 leaders from higher education, industry, and government to discuss the collaboration needed to onshore semiconductor manufacturing during the CHIPS for Virginia Summit. Held in conjunction with Northrup Grumman Corp. at its headquarters in Falls Church, Virginia, the summit showcased the university’s unique capability to serve as a conduit to support Virginia’s efforts to become a leader in semiconductors.

“None of us can do it alone and, for me, this has been the foundation for orchestrating the formation of the Virginia Alliance for Semiconductor Technology, or VAST,” Agah, the Virginia Microelectronics Consortium Professor of Engineering at Virginia Tech, said during the summit. “If there is a group of leaders positioned to help shape the future of semiconductor technology in Virginia, it is the esteemed group of stakeholders gathered here today."

10%

of all semiconductors are made in the U.S.

1,500

chips needed to outfit a single automobile

$40 Billion

value of today's power semiconductor market

Curious Conversations Podcast

Charging across traditional boundaries

Sheena Deivasigamani’s senior design project provided hands-on experience while also helping her get a foot in the door with an industry partner.

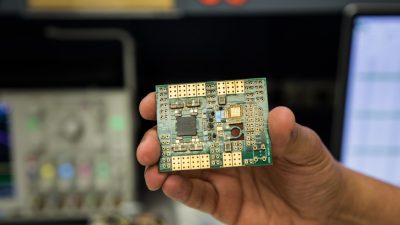

Deivasigamani, who graduated with a degree in chip-scale integration in 2023, worked alongside engineers from Micron Technology Inc. and ECE faculty to attempt to make a more flexible and organic version of random-access memory cells.

“It was great getting real feedback from our industry mentor at Micron,” she said. “Our team kept Micron up to date on our progress, and we even had a chance to visit the facility in Manassas in-person to present our work thus far.”

The experience helped land Deivasigamani a summer internship with Micron where she focused on data analysis to optimize chip functionality.

Offering undergraduate students opportunities for real-world, hands-on experience while learning from faculty and industry experts is a priority for the chips-scale integration major, for the department, and for Virginia Tech as a whole. Moving the educational experience beyond the bounds of textbooks helps jump-start students’ careers.

Graduate students yearning to learn more about the semiconductor industry are also well positioned at Virginia Tech’s Blacksburg and greater Washington, D.C., metro area locations.

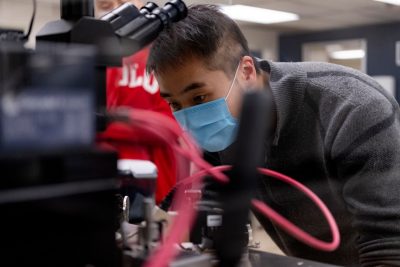

Danielle Lester, a master's student in electrical and computer engineering and graduate research assistant, is learning from some of the most accomplished researchers in the field through the Center for Power Electronics Systems at Virginia Tech. Since 1998, when the center was established as a National Science Foundation Engineering Research Center, researchers there have contributed to some of the most cutting-edge power and energy advancements in history.

Working directly with Assistant Professor Christina DiMarino at the lab in Arlington, Virginia, Danielle Lester is helping to improve the yield of high-voltage power modules with advanced packaging techniques through fabrication refinements. This technology can be applied in spaces like renewable energy and all-electric transportation.

“I love power electronics packaging because I love solving a problem at its core,” said Danielle Lester, who has no relation to Luke Lester. “And at the core of every electrical system, and every converter, is a package. Extracting all of the benefits from a semiconductor depends a lot on how you package them.”

DiMarino said that while about 10 percent of semiconductors are made in the U.S., only about 3 percent of the necessary packaging takes place domestically.

"While it is important to increase semiconductor manufacturing in the U.S., we also need to consider the packaging of the semiconductors as that is a critical step in the chip ecosystem and our manufacturing capability that we are also lacking domestically,” DiMarino said.

DiMarino is one example of faculty whose research intersects with workforce development. As the assistant director of the Center for Power Electronics Systems, she helps shape the future of packaging chips, while also introducing high school students to power electrics through internships and education programs.

DiMarino also works with researcher Yuhao Zhang, assistant professor in ECE, to advance and improve current semiconductor technologies. Zhang, DiMarino, and two more ECE researchers are improving efficiency and reducing the environmental impact of electronically driven power switches to make the multibillion-dollar industry a little greener.

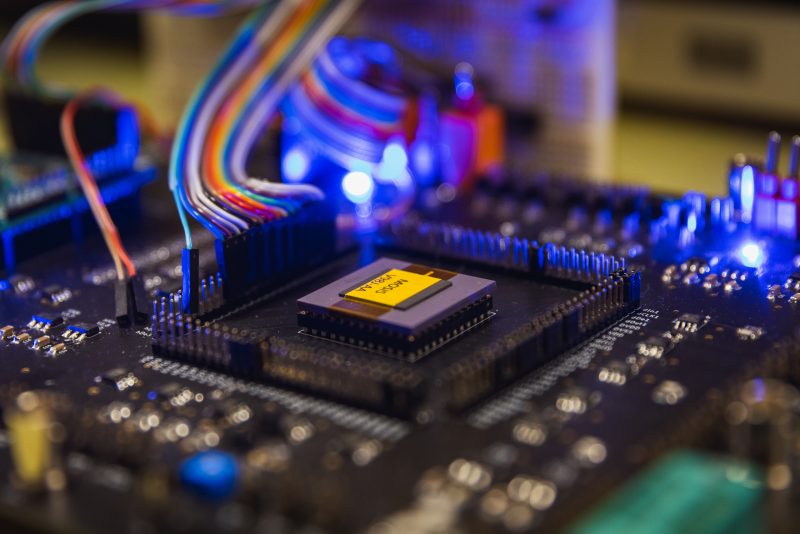

“The power semiconductor market has reached $40 billion and is forecasted to more than double that amount by the year 2030,” said Zhang. “Innovation in power semiconductors is a driver for energy savings in data centers, electric vehicles, and the electric grid. Therefore, it holds the key for realizing the unprecedented cuts in carbon dioxide for a greener and more sustainable environment.”

With similar potential to revolutionize the semiconductor industry, Associate Professor Jeff Walling has partnered with Professor Paul Ampadu and Associate Professor Cindy Yi to create artificial intelligence (AI)-enabled wireless circuits and systems.

Having received a $500,000 grant from a National Science Foundation program in partnership with Taiwan’s National Science and Technology Council, the group aims to create a healthier ecosystem for semiconductor technology innovation.

“AI-enabled millimeter wave circuit design is revolutionizing the semiconductor research landscape and driving significant advancements in U.S. chip design and fabrication,” said Yi. “By harnessing the power of AI and machine learning algorithms, researchers and engineers can rapidly explore a vast design space and identify optimal circuit configurations with unparalleled efficiency.”

Virginia Tech was one of six U.S. universities selected for the program, which will allow Ph.D. and master’s students from Virginia Tech and Taiwan universities to cross-train in both countries for an enriched research environment designed to accelerate progress in the realm of semiconductor chip design and fabrication.

Luke Lester said one of the key aspects of the chips scale integration, and all of ECE’s 14 majors, is allowing the faculty’s cutting-edge research to inform the curriculum.

There is, perhaps, no better example of that than Agah, whose research has focused heavily on the biomedical usage of semiconductors. Agah recently received a National Science Foundation award to develop a novel skin sensor using semiconductor technology that provides insight into an individual's health. For years, Agah has served as the faculty lead for the Micro Electro-Mechanical Systems Lab, where he has mentored dozens of graduate students.

“After a Ph.D. student’s first year, I try to keep a safe distance from them,” Agah said. "They probably don't know why, but I want to give them a sense of ownership. They’re not doing it [the research] for me, they're doing it for themselves — and that’s when creativity kicks in.”

After decades of helping students explore a wide range of opportunities in the field of semiconductors, Agah is now also focusing his efforts on the opportunities in the semiconductor space across the commonwealth.

VAST opportunities

For more than five years, Agah worked toward establishing a network of higher education institutions, industry partners, and government agencies with the joint mission of semiconductor research, manufacturing, and workforce development.

In April, that vision was made public when Virginia Gov. Glenn Youngkin announced a Growth and Opportunity for Virginia (GO Virginia) award of $3.3 million would fund the establishment of VAST and the accompanying adult learning program for continuing professional development, Fast Track to Semiconductor Careers. Roughly three months later, it was made official with the signing of a memorandum of understanding during the CHIPS for Virginia Summit.

“Virginia is a great home for chips, microelectronics, and technology,” Agah said. “There is a lot we can do regionally, and together we can do a lot more. This alliance leverages our collective strengths and mobilizes partners throughout the state.”

Headquartered at the Virginia Tech Research Center — Arlington, VAST will include nodes at George Mason University, the University of Virginia, Virginia Commonwealth University, Norfolk State University, and community colleges across the state while also working with Virginia Tech’s Blacksburg campus. The effort will benefit from partnerships with a range of state and local organizations, including the Virginia Innovation Partnership Corporation and the Virginia Economic Development Partnership. And it will utilize support from industry, which was led by Micron’s initial monetary commitment and includes companies such as BAE Systems and Northrop Grumman.

Along with multisector collaboration, Fast Track to Semiconductor Careers, the adult learning program, is a key component of VAST. The 10-week, certificate-based program will enroll about 300 students each year, with preference given to U.S. military veterans and underrepresented populations. The program expects to train 600 adult learners, award 550 certificates, and create 100 internships during the full two-year grant.

Kevin Crofton, a 1983 Virginia Tech graduate with more than 30 years of experience leading companies and partnerships in the semiconductor industry, said the industry really has two needs — research and development and access to talent. He believes both are opportunities for the newly established alliance to greatly impact the state.

“The member universities in VAST have an opportunity to satisfy some of those needs in a big way and as such, represent a draw for companies to come to Virginia Tech,” said Crofton, the namesake of Virginia Tech’s Kevin T. Crofton Department of Aerospace and Ocean Engineering. “It’s as simple as that.”

Agah said he not only sees opportunities for the state with VAST, but also for many departments across Virginia Tech to engage with the network in ways that keep curricula current.

“If industry is thinking about it, and the university is doing research about it, then we can start to think about creating courses or modules within courses around things that are going to happen five, 10 years from now,” Agah said. “This can help us stay at the forefront of educating students so when they graduate, they’ll be able to make the fast and necessary changes that industry requires.”

As a person who has seen first-hand Virginia Tech’s growth in the semiconductor arena, Agah said the key for future success is to continue moving forward.

“We were ahead of the game, primarily because we already have the chips scale integration major, but the game never ends. It’s never over,” Agah said. “That’s the nature of research, it never stops and it’s always opening doors. We have to remain adaptable and willing to evolve so we don’t become static because if you become static, you can’t make contributions.”

Christina DiMarino

assistant professor

Learn more about the research.

Christina DiMarino is an assistant professor in the Bradley Department of Electrical and Computer Engineering at Virginia Tech and has been the assistant director of the Center for Power Electronics Systems since 2017.

.jpg.transform/s-medium/image.jpg)