Engineering disciplines team up to fight plastic pollution

Abby Whittington is leading a transdisciplinary project to produce new biomaterials to replace single-use plastics in medical settings.

In a world reliant on single-use plastics, how can we keep ourselves and our planet healthy?

A team of transdisciplinary researchers from the Departments of Materials Science and Engineering and Chemical Engineering are working to answer that question. The team recently won grant support to begin developing biodegradable materials to eventually displace plastics used in health care facilities. Abby Whittington, a professor jointly appointed in both departments, is leading the effort.

With industry partner, Charlottesville-based NatureORAL Co., and collaborators at Virginia Commonwealth University’s School of Dentistry, Whittington and her team have received $75,000 in seed money from the Virginia Commonwealth Commercialization Fund to begin a project that could reduce the growing problem of medical waste worldwide.

Health care is one of the largest waste-producing sectors in the United States, according to the AMA Journal of Ethics. In America alone, health care facilities generate up to 14,000 tons of waste per day, including 3,500 tons of plastics. Most of that waste ends up in landfills, incinerators, or in oceans and water supplies.

The global COVID-19 pandemic only added to the pollution burden. According to a recent report from the World Health Organization, COVID-19 protective equipment and biomedical waste has contributed to increased pollution worldwide. Disposal challenges of hazardous wastes, especially in developing nations, can even threaten human health.

“Solving this problem requires us to think about the entire waste cycle from beginning to end,” Whittington said. “The team’s starting point is creating and testing new materials that can be used for food wrappers and packaging for medical supplies.”

It’s a complicated problem. While medical plastics can be made of recycled materials, they themselves often can’t be recycled, Whittington said. Once plastics like syringes are used, they are considered hazardous waste. They must be sterilized in an autoclave and sent to a landfill, or they must be incinerated.

Packaging is a good place to start this research because medical and dental equipment often come wrapped in films to keep them clean, but these plastics typically don’t end up as hazardous waste.

“Our first step is to develop a sugar-based film that can displace some single-use plastics that are traditionally petroleum-based and either don’t degrade or break down very slowly. Using biomaterials will allow the waste to degrade more quickly in a variety of environments,” Whittington said.

What the team learns can then inform development of new materials for other, higher-risk plastics used in health care settings.

“This grant will help us develop a prototype and get some of the kinks worked out of the current formulation, so we can determine degradation times and also develop films that are large enough that we can then share with our collaborators at Virginia Commonwealth University in the School of Dentistry,” Whittington said.

The thrust of the project is threefold: define, develop, and test the materials for plastic substitution; generate patents for those discoveries; and license and manufacture new products for industry use.

“With so many countries — including the U.S. — recognizing and seeking alternatives to plastics, the commercial market is ripe for such a disruptive technology,” said Vincent Mascia, president of NatureORAL.

The work shows the importance of different engineering disciplines working together to solve global problems.

“From the materials science and engineering perspective, we’re looking at how we’re changing the formulation and processing of new materials and measuring how well they function for purpose and how fast they break down in various situations,” Whittington said. “From the chemical engineering side, we’re asking: how do we scale this up; what are the impacts of the changes in the viscosity of the material; how is that influencing our process?”

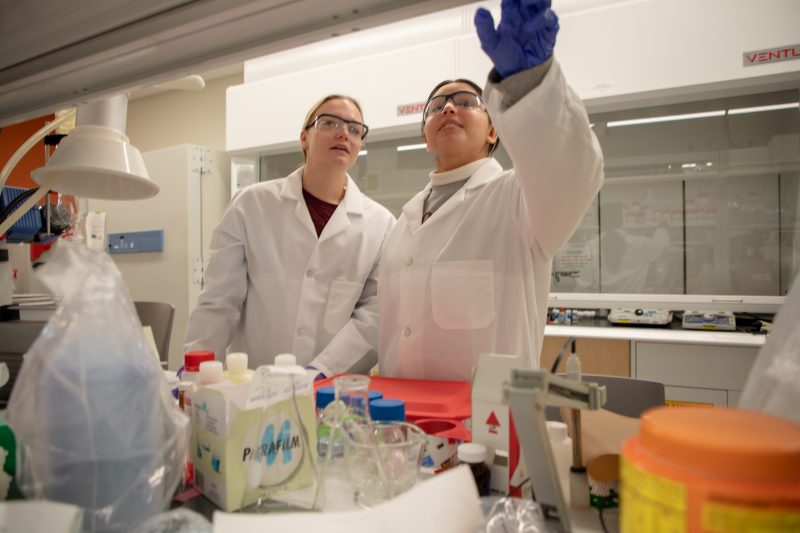

To bring these disciplines together, Whittington assigned materials science graduate student Selma Gmati and chemical engineering undergraduate Aley Savory to the project. Gmati will write her master’s thesis on this work, and it gives Savory credentials that will help her secure a job in industry. But for both students, it’s also about engineering for a higher purpose.

“I've always known that I want to work with my skills in the health and medicine field because I like that idea of using materials science to help others,” Gmati said. “To know your work has a global impact, or answers a national question, or even just helps one community — it’s heartwarming.”

For Savory, it’s also a mix of practical and purposeful work.

“I'm really excited to learn about what a chemical engineer can do in partnership with materials scientists and dental professionals,” Savory said. “Most likely after graduation, I'll be going into industry, so hopefully having some of those skills, having some of that interdisciplinary understanding will make me a better engineer.

And, she said, “working on a health care issue and on reusability and sustainability — it's awesome to be a part of a team that's doing that.”