New coal dewatering technology turns sludge to powder

Because there has been no economically viable technology to remove water from ultrafine coal slurries, the ultrafine particles that are the residue of the coal cleaning process have been discarded into hundreds of impoundments. Now, Peter Bethell of Arch Coal Inc. reports that a dewatering technology developed at Virginia Tech has succeeded in reducing the moisture content of ultrafine coal to less than 20 percent, transforming it to a salable product.

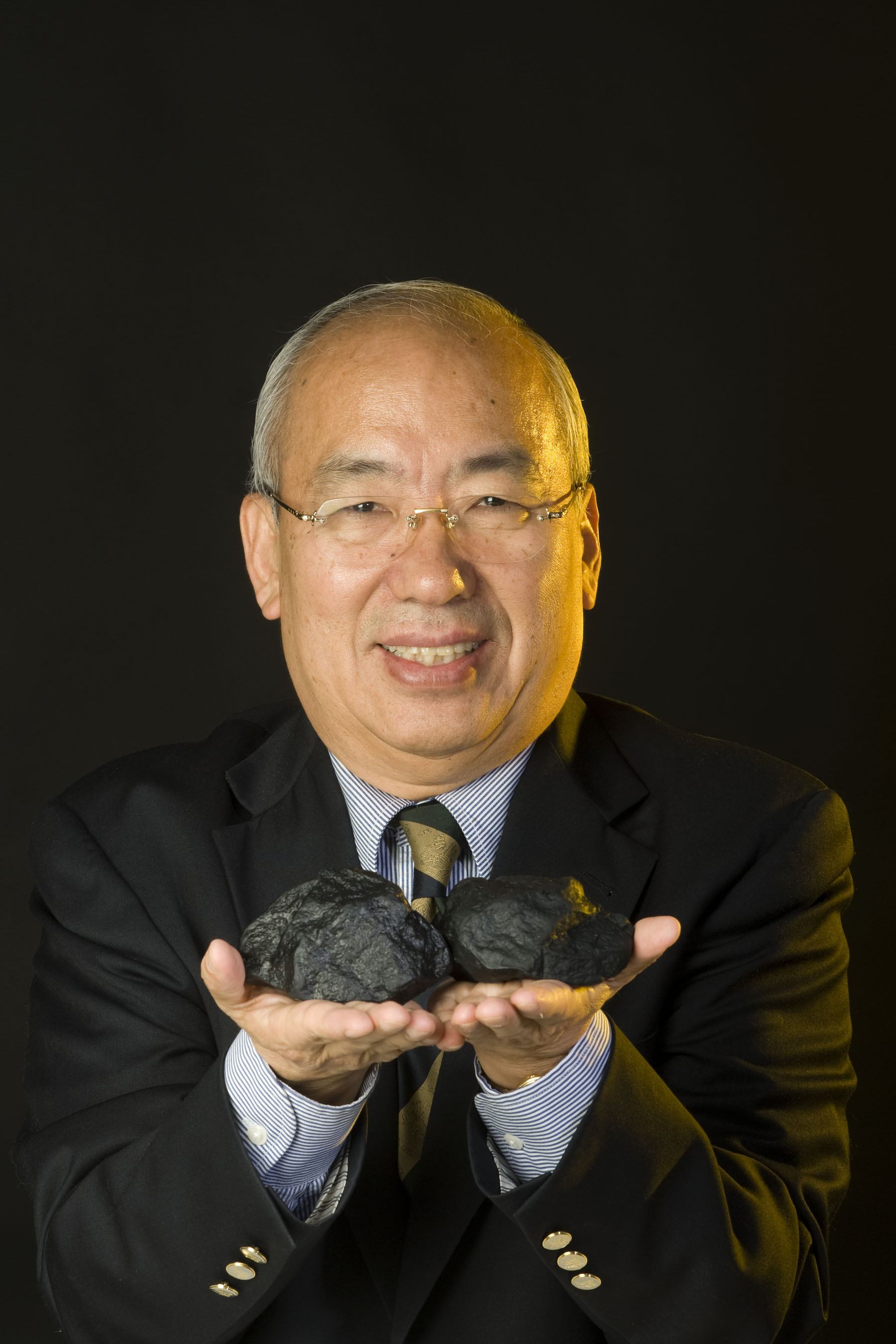

With funding from the National Energy Technology Laboratory (NETL), Roe-Hoan Yoon , the Nicholas T. Camicia Professor of Mining and Mineral Engineering in Virginia Tech’s College of Engineering, and his colleagues have developed a hyperbaric centrifuge that can efficiently dewater coal as fine as talcum powder. Such coal fines presently must be discarded by even the most advanced coal cleaning plants because its moisture content in conventional dewatering systems make it unmarketable.

"The hyperbaric centrifuge is like the spin cycle on a washing machine, with the addition of compressed air," said Yoon. "Combining increased spinning and compressed air has a synergistic effect and cuts the moisture in half compared to conventional technology."

"The results were very favorable," said Bethell, director of coal preparation at Arch. "This is material we would have had to discard; therefore, such success would mean reduced refuse in the environment and improved economic returns for the company. It also goes to energy independence because we are using more of the available resource," said Bethell.

"The Arch results mean a lot for getting the Centribaric TM technology started," said Wally Schultz, executive vice president at Decanter Machine Inc. of Johnson City, Tenn., which built the prototype unit that was used at Mingo Logan Coal Company’s Cardinal Preparation Plant, a subsidiary of Arch Coal. "The prototype unit was trailer mounted and capable of processing approximately 30 gallons per minute of feed slurry," said Schultz, who was onsite for the tests.

Decanter has been in business since the late 1980s and is the industry leader in screen-bowl centrifuge technology. "We view the Centribaric centrifuge as an extension of our product line to further recover fine coal. Previous centrifuges have not used the compressed air component," Schultz said.

"There has been no technology to economically dewater coal fines below 44 microns," said Yoon. "Now this technology can be used in conjunction with the MicrocelTM technology, developed many years ago to remove ash, to re-mine the fine coal discarded to impoundments and to help companies minimize waste generation.

"For me, that is a great accomplishment," said Yoon. "People living in coal mining districts will see fewer and smaller slurry ponds. We have done something for the industry and for the public."

"The whole purpose of cleaning coal is to reduce the ash content so that the users, usually utility companies, don't have to deal with it," said Gerald H. Luttrell, the Massey Professor of Mining and Mineral Engineering at Virginia Tech. He added that "the lower-ash and lower-moisture coals also produce less CO2 (carbon dioxide) to clean up. They burn more efficiently and thus require less coal to generate a given amount of electricity."

For this reason, Yoon and Luttrell have received $1 million in funding from the U.S. Department of State to also help the Indian coal industry produce a cleaner product. And the Virginia Tech researchers anticipate another project to be funded by Coal India Limited (CIL), the largest coal company in India, with the same a similar objective. The U.S. Department of Energy has been negotiating with CIL for this project on behalf of Virginia Tech.

However, plans to install the new technology in the United States may be stalled. During the recent economic downturn, the price of coal dropped precipitously, which may be a barrier for immediate installation of commercial-scale units at plants. "But when the market improves, we will probably be able to justify spending the capital to install full-scale units," said Bethell, who has been working with Yoon's group for more than 20 years. "We both have Ph.D.s in similar fields, and I like to make sure that we liaise with academia so that if there is anything new we can consider using it." Bethell was the first to implement the Microcel technology.

Yoon arrived at Virginia Tech in 1979 from Canada. With funding from the U.S. Department of Energy, he and his colleagues, Luttrell and Professor Greg Adel, studied the collision between bubbles and particles in water. This fundamental study led to the development of the Microcel technology, which is used widely in the mining industry and is considered the best for cleaning fine coal. The group has developed many other technologies that are also in commercial use.

Yoon is the founding director of the Center for Advanced Separation Technology, a consortium of seven universities including Virginia Tech, West Virginia University, University of Kentucky, Montana Tech, University of Nevada at Reno, New Mexico Tech, and the University of Utah. Its goal is to develop advanced separation technologies as applied to energy resources and environmental control.

In October 2008, Yoon was elected to the National Academy of Engineering — the highest honor in engineering. He earned his Ph.D. in metallurgical engineering from McGill University in 1977. He obtained his bachelor's in mining engineering from Seoul National University in 1967.

.jpg.transform/m-medium/image.jpg)