Tale of two musicians leads to partnership that spans polymers to bio-based materials

In the 1970s, a tale of the friendship of two men began. Both were musicians by hobby, but their real vocations were as scientist and engineer. Their friendship and respect for each other started an educational partnership that has now spanned some four decades and helped to provide Virginia Tech with one of the best interdisciplinary materials programs in the world.

James McGrath’s nameplate was nailed on a door of the Virginia Tech chemistry department, located in antiquated Davidson Hall, in 1975. Three years later, a young chemical engineer by the name of Garth Wilkes left his job at the Ivy League Princeton University to work in Randolph Hall, one of Virginia Tech’s oldest engineering buildings. Together, they started the state-of-the-art Polymer Materials and Interfaces Laboratory, the first true interdisciplinary research center that crossed college boundaries at Virginia Tech.

Following their lead, other chemists like Tom Ward, Larry Taylor, and Jim Wightman joined the Polymer Materials and Interfaces Laboratory, as did chemical engineers Don Baird and Richey Davis. Other disciplines gravitated toward the stimulating work on materials of the future. Dave Dillard of engineering science and mechanics and Wolfgang Glasser of wood science and forest products were among the earliest cooperating faculty.

“We had the right administration to make this work,” Wilkes says. “Paul Torgersen was dean of engineering and he told us to go for it. He nurtured our group, as did the then-dean of science, Henry Bauer. The timing was also good as Virginia Tech was looking for visibility in the late 1970s in the research area. With Jim and I as co-directors, science and engineering were co-owners across the campus. The key was that people held hands as a family, and we sold our work as one program.”

Since the laboratory’s start in 1978, Virginia Tech scientists and engineers have excelled in polymer science and engineering. “Our product is and was the student who bridged several disciplines,” Wilkes says. The scientists and engineers taught materials classes as a team, and one of the more visible components of their work was the short courses they offered through the American Chemical Society.

Over the years, one course, Principles and Practices of Polymer Chemistry, was offered more than 166 times to some 5,000 researchers. “We started with the big boys,” Wilkes smiles. The students were the men and women already working at such industrial giants such as Shell, Mobile Oil, Exxon, Dow, and Dupont. Later, the swing went to smaller companies concentrating on biomaterials and nanotechnology.

Complementing the Polymer Materials and Interfaces Laboratory’s materials research, Engineering Science and Mechanics Professor Hal Brinson organized the Center for Adhesion Science and Ken Reifsnider founded the Center for Composite Materials and Structures, both in 1982. The Center for Adhesion Science soon became the Center for Adhesive and Sealant Science. Researchers within the groups overlapped, and they were credited with numerous discoveries, such as the development of techniques to investigate damage states in composites — methods implemented in research labs around the world.

The commonwealth recognized the vast array of talent at Virginia Tech, saying its critical mass allowed for developing a world-class center, and so it established the $1.3 million Virginia Institute for Material Systems at the university in 1988. The Virginia Institute for Material Systems encapsulated the work of the faculty of Polymer Materials and Interfaces Laboratory, Center for Adhesive and Sealant Science, and Center for Composite Materials and Structures, as well as others across the state.

By now, the Polymer Materials and Interfaces Laboratory was already listed in the top five of its kind; the Center for Adhesive and Sealant Science, the only such university-based center at the time, had a $5 million endowment fund; and the Center for Composite Materials and Structures was rated number one in the country in terms of size and breadth of its composites activity with expenditures of more than $2 million annually.

In 1989, the National Science Foundation established the world-class center the state had thought possible — the foundation’s Center for High Performance Polymeric Adhesives and Composites — at Virginia Tech. A 10-year multimillion-dollar venture, the investigators focused on creating materials advances for the aerospace industry during their initial work. Later, the researchers applied these innovations to a variety of other business sectors. Among numerous specific accomplishments, they prepared linear thermoplastics and toughened thermosetting materials and processed them into adhesives, prepregs, and composites, a first for a university facility.

They demonstrated improved fracture toughness in composites. And they used a special technique to make carbon fiber composites and laminates. They improved the safety of manufacturing specific composites by eliminating the need to use solvents that were associated with flammability and pollution.

Since the National Science Foundation center status is designed to last a maximum of 10 years, the Center for High Performance Polymeric Adhesives and Composites dissolved in name by the turn of the century, but the interdisciplinary work continued. More recently, in 2004, this collaboration resulted in the formation of the Macromolecules and Interfaces Institute.

The Macromolecules and Interfaces Institute represents the convergence of the three internationally known centers, as well as an institute and a graduate degree program. The participating institute in the Macromolecules and Interfaces Institute is the Materials Research Institute, also founded by McGrath in 1987.

The graduate program is the interdisciplinary macromolecular science and engineering degree, approved by the State Council for Higher Education in Virginia in 2001 and directed by Judy Riffle of the chemistry department. Today, the Macromolecules and Interfaces Institute consists of about 20 faculty members, many of whom are new faculty, who are heavily involved in polymer, adhesion, and composite research, along with over 30 additional faculty members involved in peripheral ways.

Dillard, a past director of the Center for Adhesive and Sealant Science, spearheaded the efforts to bring the related areas under one university organization. “I wanted to take away the boundaries. Most of the faculty belonged to all five entities, and it was confusing where one organization stopped and another started,” Dillard said.

Dillard credits Virginia Tech’s extraordinary success in materials research to the personalities of some of its founders, many of whom are now retired or semi-retired. “Garth Wilkes, Jim McGrath, Hal Brinson, and Jim Wightman were all highly competent scholars who did things for the good of the group, and the university greatly benefited from their actions,” Dillard says. In turn they recruited some very good people, he adds, “and we were able to provide the interdisciplinary academics better than most of our competitors. People as brilliant and famous as Garth and Jim took us under their wings, and we have a tremendous foothold in materials research based on what they established.

“Ken Reifsnider (now an emeritus engineering science and mechanics faculty member and a National Academy of Engineering member who has moved his work to the fuel cell arena) laid the framework for the modeling of composites. At Virginia Tech, we are known for stress analysis,” thanks to his initial efforts, says Dillard, who today holds the Adhesive and Sealant Science Endowed Professorship.

Materials research at Virginia Tech is now “morphing into the energy area. We have to solve the energy problem and its future contains a portfolio of energy solutions. Polymers are playing a big role in fuel cell development,” Dillard says.

Dillard, Scott Case, and Michael Ellis, also engineering faculty members, are researching fuel cell membranes for General Motors. And McGrath has also moved in this direction, working with his group to improve fuel cell materials, specifically polymer-based proton exchange membranes. Read a comprehensive overview of the project.

“[The Macromolecules and Interfaces Institute] is well-positioned to be a leader in contemporary advanced materials growth themes of importance to the commonwealth,” McGrath, a member of the [National Academy of Engineering] since 1994 and a University Distinguished Professor, says. In addition to the fuel cell energy systems research, MII researchers continue work on high-performance adhesives and composites, novel biomaterials, and unique nanostructured materials and novel thin films.

Another part of the Macromolecules and Interfaces Institute’s objective is to enhance economic opportunities within the region and the state through spin-off ventures, interactions with the Advanced and Applied Polymer Processing Institute in Danville, and other initiatives. Current research includes contracts with such companies as 3M, Avery Dennison, Battelle, Boeing, Daimler-Chrysler, Dow, DuPont, Hewlett-Packard, IBM, Johnson and Johnson, Luna, and NanoSonic.

“MII serves as a research engine. Building on our strengths and common interests, this organization is developing a program that can maintain and improve our national ranking from our current fifth place position in the last polymer materials survey done by U.S. News & World Report, positioning us for new funding opportunities in growth areas relevant to our expertise,” Dillard says.

The institute’s faculty includes members of the colleges of Agriculture and Life Sciences, Business, Engineering, Natural Resources, Science, and the Virginia-Maryland Regional College of Veterinary Medicine. Directing the Macromolecules and Interfaces Institute is Richard Turner, a research fellow with Eastman Chemical Company’s Polymer Technology Division, who joined Virginia Tech in January 2005.

Turner, who holds more than 100 patents and was recently named the 2008 winner of the American Chemical Society Division of Polymer Chemistry’s Industrial Polymer Scientist Award, earned his Ph.D. in organic polymer chemistry from the University of Florida, Gainesville, in 1971, followed by postdoctoral work in polymer chemistry in Darmstadt, Germany. He has worked in the research laboratories of Xerox Corporation, Exxon Mobil Corporation, Eastman Kodak Company, and Eastman Chemical Company.

With the wealth of talent in the materials field at Virginia Tech, the Army Research Laboratory established the Multilayered Technologies for Armored Structures and Composites Materials Center of Excellence at the university in 2006. Administratively positioned within the Macromolecules and Interfaces Institute, its purpose is to develop polymer-based materials to protect personnel and equipment against weapons attack. The center also offers graduate student and postdoctoral scholar mentorship and undergraduate research programs. It involves researchers from eight interdisciplinary research groups, two colleges, and six academic departments at Virginia Tech, who are teaming with personnel at the ARL Weapons and Materials Research Directorate. Tim Long of chemistry and Romesh C. Batra, engineering science and mechanics professor, are the co-technical directors.

The ARL award provides $500,000 per year, potentially renewable for nine years, totaling approximately $4 million. The Virginia Tech Multilayered Technologies for Armored Structures and Composites Materials Center of Excellence center researchers are developing structural materials with chemical resistance, thermal stability, and fracture resistance; transparent materials that are self-healing with anti-reflection and anti-abrasions surfaces; and new, efficient manufacturing processes to create multi-functional, multi-layered materials.

“The future of materials research is moving toward the bio-based materials, nanotechnology, and green engineering,” Wilkes says. For example, he is working with a company on a biodegradable heart stent that is now in clinical trials. “It will do its job and then destroy itself,” Wilkes explains. “We are also looking at the possibility of organic based light-emitting diodes…Green technology is definitely carrying more weight as it is important to consumers and new legislation is coming from government organizations.”

Wilkes points to a recent issue of the trade journal Chemical and Engineering News, which claims that venture capital funds are also turning to “cleantech” and that green start-ups “will constitute their (venture capitalists) highest growth sector in 2008.” Virginia Tech materials engineers and scientists again plan to be in the forefront.

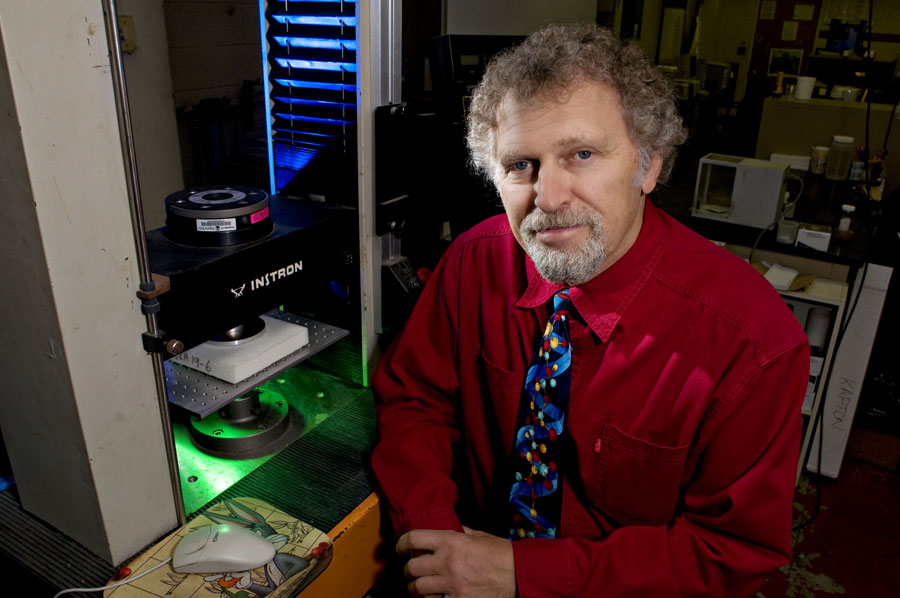

IMAGE INFORMATION: Garth Wilkes, professor emeritus of chemical engineering, is one of the original founders of the Polymer Materials and Interfaces Laboratory four decades ago. Today, the laboratory is part of the Macromolecules and Interfaces Institute, representing the convergence of the materials research at Virginia Tech.

.jpg.transform/m-medium/image.jpg)