Researchers improve productivity at Devil's Slide tunnels with National Science Foundation-funded software

Virginia Tech engineers have developed exciting new software technology, geotechnical Visualization Tools (gVT) that allows the use of 3-D visualization for making detailed maps of rock masses – either above or below ground, as they are exposed by excavation.

The software is being used by the engineers in the construction of twin roadway tunnels for the California Department of Transportation, which will relocate coastal Highway 1 away from a recurring, damaging landslide known as Devil's Slide.

The benefits of using this technology are that it accelerates collection of critical engineering geologic information, creates a digital record of the rock that can be accessed at any time, and reduces worker exposure to hazardous situations.

Development of this innovative software is supported by a grant from Information Technology Research Initiative of the National Science Foundation. gVT is the result of research directed by Joseph Dove, research assistant professor of civil and environmental engineering at Virginia Tech, with former graduate students Brian Badillo and Jeramy Decker. Badillo is now a software engineer, and Decker is a geotechnical engineer with Kiewit Pacific Company, one of North America's largest and most respected construction and mining contractors. It is constructing the twin tunnels.

Working underground is fraught with challenges to engineers and danger to workers, Dove said. Rock masses made unstable by the intersection of discontinuities –– breaks in the rock–force expensive design and construction changes –– resulting in cost overruns on construction projects. Rockfalls, roof collapse and rock "bursts" result in over 3,500 injuries or deaths each year to underground workers.

These problems are partially addressed by exploring the subsurface by drilling during design and before construction begins. However, it is impossible to examine the subsurface conditions in sufficient detail beforehand. Consequently, it is important that engineers constantly make measurements of the orientation of the rock discontinuities as they are exposed during construction. However, even collecting this information exposes workers to dangers and, in some cases, the discontinuities are far overhead or distant and cannot be reached. The advantage of manual measurements is that the engineer can see the rock surface in three dimensions.

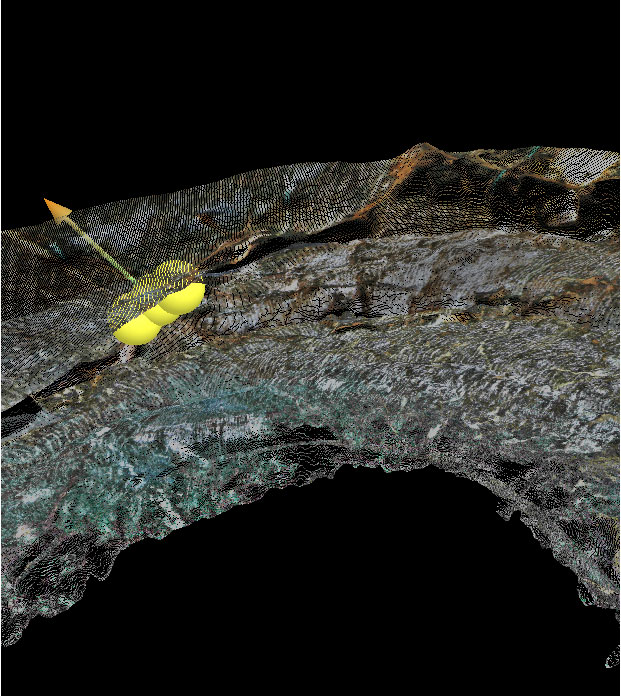

The new technology employed at the Devil's Slide project uses a tunnel laser scanning system to acquire data for 3-D visualization from the tunnel's interior during excavation. Laser scans consist of closely spaced data points collected by reflecting a laser pulse off of the rock surface many thousands of times in a defined pattern. The points, collectively known as a "point cloud," have their positions in space referenced by traditional survey measurements. The gVT software allows visualization of these data in three dimensions along with the capability to assess geological conditions from the safety of an office computer, Dove explained.

"gVT is an exciting productivity tool for design and construction. Seeing it make an impact on a major infrastructure project is rewarding" according to Dove, a co-principal investigator on the National Science Foundation-Information Technology Research Initiative project. "The overall goal of the multi-investigator [research initiative] project is to create a system that integrates several technologies to give an engineer the ability to predict a tunnel's mechanical behavior meters ahead of the current excavation limit. If problems are anticipated, the design or construction methods can be adapted to meet those conditions. gVT serves as the 'eyes' of this system," Dove added.

The use of gVT at Devil’s Slide has greatly enhanced the scanning data obtained during the excavation allowing up to 10 meters of tunnel geology to be viewed in 3-D at a time. "3-D visualization of the tunnel gives an impressive view of the geology that is not even experienced in the tunnel itself due to the concrete lining being applied shortly after each excavation round" says Decker. 3-D visualization enhances the geological documentation of the exposed rock surfaces and allows measurement of the orientations of any rock discontinuities present. Discontinuity orientations can be verified against field measurements and new measurements can be made of discontinuities that are difficult or unsafe to measure in the field.

gVT's success in the Devil's Slide tunnels is an important step in furthering the use of scanning technology in underground construction, and research on this technology continues at Virginia Tech. A presentation of the scanning technologies and techniques being used in the Devil's Slide tunnels was made by Decker in the workshop "Laser and Photogrammetric Methods for Rock Tunnel Characterization" as part of the 42nd U.S.–Canada Rock Mechanics Symposium held in San Francisco, June 29.

.jpg.transform/m-medium/image.jpg)