From wafers to chips: Virginia Tech is satisfying the craving for semiconductor advancement

Students, faculty, and alumni of the Bradley Department of Electrical and Computer Engineering are answering the call for semiconductor technology advancements from classrooms and labs to the workplace and even our nation’s capital.

Chips. What are they and what’s Virginia Tech’s role?

When it comes to CHIPS, it’s true what they say. You can’t have just one. OK, so we’re not talking about those kinds of chips, but the concept still rings true in the case of these semiconductor devices.

The small microchips can be found in almost every electronic device we use today. From vehicles and computers to appliances and medical equipment. And if the pandemic taught us anything, it’s that shortages of semiconductors can be devastating for not just businesses and industry, but for individuals as well.

CHIPS in the CHIPS and Science Act stands for Creating Helpful Incentives to Produce Semiconductors, and Virginia Tech is doing its part to help find viable solutions for the immense demand in research and development as well as manufacturing. The land-grant university is leading the way with faculty expertise, state-of-the-art facilities, and a history of service.

With Ut Prosim (That I May Serve) at the forefront, faculty spearheading these initiatives recognize the important role that the College of Engineering will play in the years ahead when it comes to increased semiconductor development and manufacturing in the commonwealth.

“We’re excited about this opportunity because we are not only going to change the world and make other people’s lives better, but we also get to provide our students with that same opportunity through experiential learning,” said Luke Lester, head of the Bradley Department of Electrical and Computer Engineering. “They get to be part of this national priority to become more globally competitive in the semiconductor space.”

The department (ECE) offers 14 majors for undergraduate students. One of those is the semiconductor chip-scale integration major. It was created during a revamp of the electrical and computer engineering curriculum as part of the National Science Foundation Revolutionizing Engineering Departments Grant. Since its inception, the major has seen a sevenfold increase in the number of students declaring and graduating with a specialization in chips.

In addition to cutting-edge curriculum, ECE is part of major semiconductor efforts in Virginia and beyond.

The Virginia Alliance for Semiconductor Technology is a statewide semiconductor network that will create a pathway toward a semiconductor network and workforce opportunities with an adult learning program to boot. Professor Masoud Agah is leading this effort as the alliance's founding director. Virginia Tech also is part of the Northeast University Semiconductor Network formed by Micron Technology Inc. This network of 21 universities will drive foundational and emerging research to increase students’ opportunities for experiential learning across the semiconductor ecosystem.

On July 18, Virginia Tech hosted the CHIPS for Virginia Summit in Washington D.C., convening industry, government, and academic leaders for a critical conversation on how to propel Virginia forward in the semiconductor economy and celebrate the Virginia Alliance for Semiconductor Technology network.

Learn more about the semiconductor buzz from Virginia Tech voices navigating the CHIPS landscape.

The undergraduate undertaking

Undergraduate students are getting real-world, hands-on experience in Virginia Tech’s semiconductor lab spaces while learning from faculty and industry experts. Taking the educational experience outside the bounds of textbooks gives students the tools they need to be ready for the workforce after graduation.

Sheena Deivasigamani '23, computer engineering

ECE students are also gaining invaluable experience with guidance from industry experts. As part of her senior design project, Sheena Deivasigamani, who graduated with a degree in chip-scale integration worked on random-access memory (RAM) cells with the goal of creating a more flexible, organic version.

“It was great getting real feedback from our industry mentor at Micron,” she said. “Our team kept Micron up-to-date on our progress, and we even had a chance to visit the facility in Manassas in-person to present our work thus far.”

With advice from professional engineers at Micron and ECE faculty, Deivasigamani learned more about semiconductor fabrication than she ever thought possible in a two-semester course.

The experience landed her an internship with Micron. Deivasigamani joined a cohort of 2,500 team members at the Manassas facility in May for a summer internship focusing on data analysis to optimize chip functionality.

“I'm super excited about the internship,” said Deivasigamani. “The day I found out I was selected, I texted all of my friends to share the news. It feels really cool to be part of a company that has huge stakes in producing chips while innovating its processes and products.”

In addition to its recent $3 million facilities expansion in Manassas, the CHIPS Act stakeholder recently announced the Northeast University Semiconductor Network. The new partnership focuses on collectively developing the next generation of the U.S. semiconductor industry’s workforce and features 21 founding member institutions, including Virginia Tech.

Learn more about Micron's UPWARDS for the Future program.

Anshu Madwesh '23, computer engineering

Anshu Madwesh also earned his degree in computer engineering with a major in chip-scale. He was most excited about the opportunity to use what he learned in the cleanroom and in the classroom in a real-world context.

“Chip-scale integration taught me that the semiconductor field is much deeper than what meets the eye. The curriculum introduced me to concepts at different levels of the chip design process,” said Madwesh. “I enjoyed learning how to use the different tools and machines in the cleanroom and plan to carry these skills of the tools and machines into industry.”

For Madwesh, the hands-on work in the semiconductor fabrication lab for his senior design project combined with the in-depth classroom concepts paid off – literally. He started a new job as an applications engineer at Texas Instruments in Dallas. In this role, Madwesh designs and improves applications of chips while serving as the direct link between the customer and the engineering team. He gathers the unique goals of a project from clients and then implements those requests.

“At TI as an applications engineer, a big aspect of my role is working with customers to dissect design challenges and work to create solutions for these challenges,” said Madwesh. “My Major Design Experience project prepared me for this role by allowing my team to continue work based on progress from students in semesters prior, and find new solutions based on customer needs.”

Graduate students get in the game

Student experiences don’t stop at the undergraduate level. Graduate students yearning to learn more about the semiconductor industry are well positioned at Virginia Tech’s Blacksburg and Northern Virginia campuses.

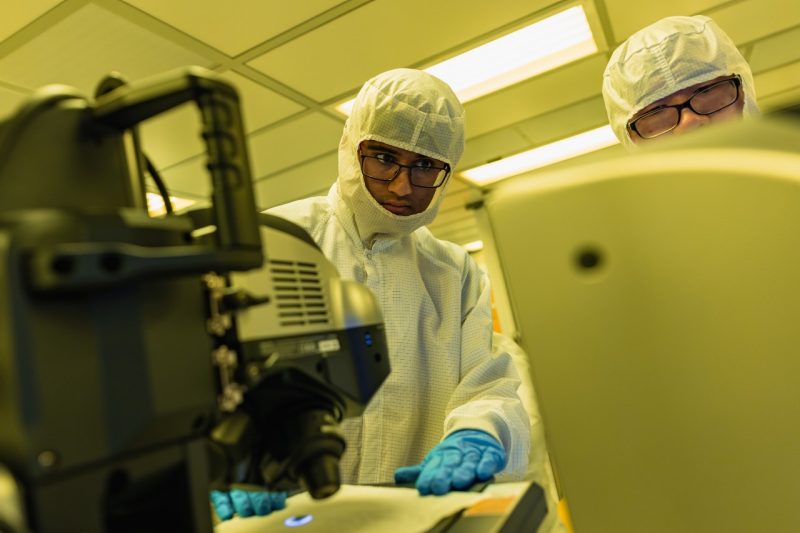

Amrita Chakraborty, Ph.D. student in electrical engineering

Graduate student Amrita Chakraborty is researching nonvolatile resistive RAM and organic polymer-based electrodes for flexible electronic devices. She has always been interested in the semiconductor industry and plans to join the semiconductor manufacturing industry after she graduates to apply her extensive experience in electronic device development and fabrication.

In addition to her own research, Chakraborty mentors students in ECE’s senior design capstone known as the Major Design Experience. This course gives students hands-on experience in the cleanroom and allows them to learn real techniques used by companies in the semiconductor industry. She has mentored over 45 undergraduates on cleanroom-based projects and led over 11 teams as a subject matter expert.

“My journey as a Ph.D. student thus far has been one of the best experiences of my life,” said Chakraborty. “I have learned a lot about myself and have been fortunate enough to pass down my knowledge and interest in semiconductor fabrication to undergraduate students in the department. They get a glimpse of the inner workings of semiconductor device fabrication, while getting hands-on experience working with semiconductor companies acting as their clients.”

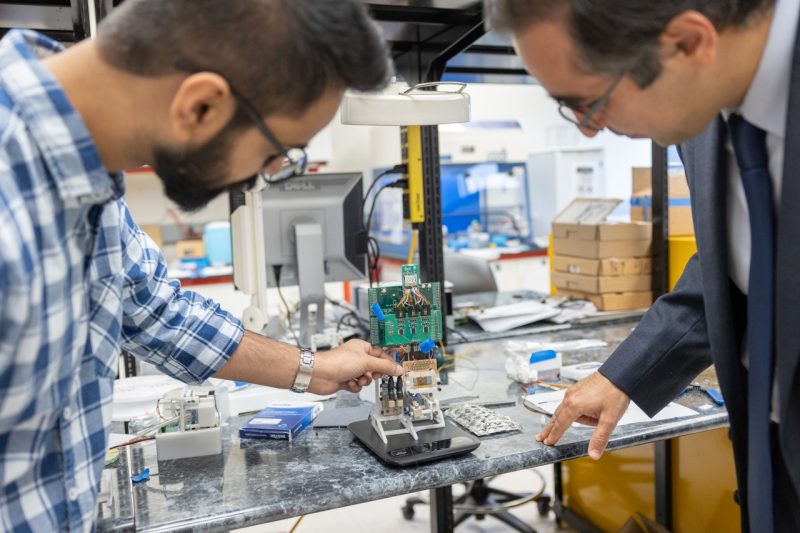

Danielle Lester, master's student and graduate research assistant

Danielle Lester, a master's student in ECE, is getting the opportunity to learn from some of the most accomplished researchers in the field through the Center for Power Electronics Systems at Virginia Tech. Since 1998, when the center was established as a National Science Foundation Engineering Research Center, powerhouse researchers have contributed to some of the most cutting-edge power and energy advancements in history.

Lester works directly with one of the center's newest heavy hitters, Assistant Professor Christina DiMarino. At the Center for Power Electronics Packaging Lab in Arlington, Lester and DiMarino focus on fabrication refinements for multi-chip power modules. The work will improve the yield of high-voltage power modules with advanced packaging techniques and can be applied in spaces like renewable energy and all-electric transportation.

“I love power electronics packaging because I love solving a problem at its core,” said Lester. “And at the core of every electrical system, and every converter, is a package. Extracting all of the benefits from a semiconductor depends a lot on how you package them.”

One of the best examples DiMarino has given Lester in terms of packaging is the analogy of taking a Ferrari engine and packaging it into a Toyota Corolla. The original Corolla might be reliable and cost-effective, but it can't quite extract all the capabilities that the engine of a Ferrari can offer in that package.

“The Ferrari-Corolla example is a great way to view the motivation to improve the packaging of semiconductors for the future,” she said.

From students to alumni

Virginia Tech ECE alumni who graduated with a focus or research expertise in chip-scale integration have found that their education has served them well in industry and academia.

Christine Whiteside ‘17

Christine Whiteside is a hardware development engineer at IBM. She works in the IBM Infrastructure Group that designs and develops world class microprocessor chips used in IBM’s System Z mainframe computers. These machines deliver the highest levels of reliability, security, and quickly execute some of the largest transaction workloads — think large banks, airlines, insurance, and retail.

Whiteside understands the importance of her education from Virginia Tech and the readiness it provided her when searching for industry jobs after graduation.

“My education from ECE has been invaluable to my success at IBM,” said Whiteside. “I knew that I wanted to learn more about microelectronics and semiconductors once I started getting deeper into the electrical engineering course work at Virginia Tech. Now that the semiconductor space is exploding thanks to the CHIPS Act, it is important that we keep improving and advancing the curriculum so that current and future students can transition into those technical jobs once they graduate.”

Whiteside has been a member of the Virginia Tech ECE Advisory Board since 2018 and currently serves on the executive committee. She plays a big role in continuous improvement of the curriculum to ensure that students are learning the information that is critical to their future as professional engineers.”

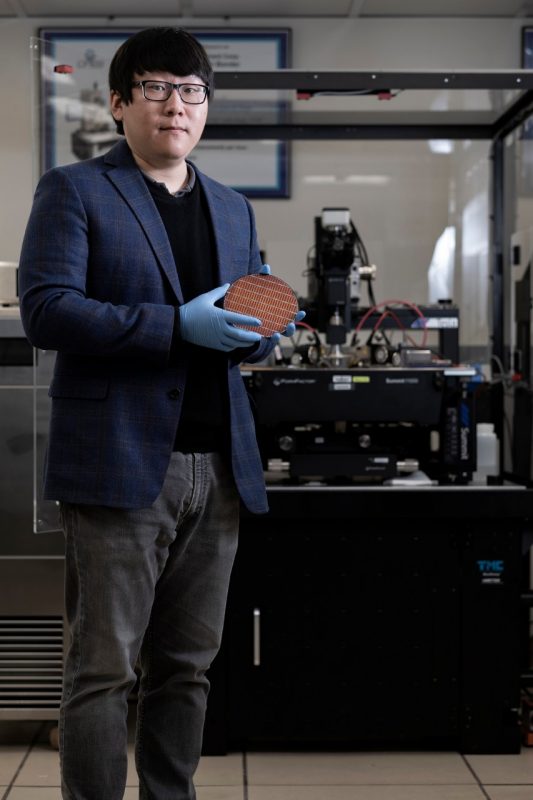

Hongyu An Ph.D. '20

For Hongyu An, the semiconductor industry was always an intriguing career path. But after working with Cindy Yi in the Multifunctional Integrated Circuits and Systems (MICS) Lab, it was clear that continuing in academia was his true passion.

“Professor Yi and other faculty in the MICS Lab played a significant role in broadening my perspectives in the semiconductor field,” said Ha. “The mentorship I was given throughout my doctoral training made my learning experience truly exceptional. That experience has inspired me to continue my research and provide the same support for my current students.”

An is an assistant professor at Michigan Tech University and leads the Brain-Inspired AI Lab. He currently teaches very large-scale integration (VLSI) courses to undergraduate students. VLSI is the process of creating an integrated circuit by combining hundreds of thousands of transistors into a singular silicon semiconductor microchip. This process improves efficiency, reduces size, and results in higher device reliability.

“The mastery of semiconductor technologies and microchip designs cannot be achieved solely through reading books,” said An. “It is essential to engage in hands-on design when you have the actual ‘chip’ in your hands."

The assistant professor has integrated the design of AI chips into the courses he teaches at Michigan Tech. In doing so, his students are experiencing cutting-edge microchip designs for next-generation AI computational platforms firsthand.

Faculty feed the need for chips

With cutting-edge research from several faculty members, the department is doing its part to innovate these technologies and move the needle on semiconductor development in the commonwealth and beyond.

Masoud Agah, professor, Micro Electro-Mechanical Systems faculty lead, founder of Virginia Alliance for Semiconductor Technology

Masoud Agah is a prime example of the leadership and expertise needed to put Virginia Tech on the map and contribute in a way that extends beyond the Blacksburg campus’s Hokie Stone walls. His research has focused heavily on the biomedical usage of semiconductors. Most recently, he received a National Science Foundation award to develop a novel skin sensor using semiconductor technology that provides insight into an individual's health.

He’s been a key player in the semiconductor space for years as the faculty lead for the Micro Electro-Mechanical Systems Lab and has mentored dozens of graduate students along the way. Agah remembers his time as a Ph.D. student and the trust he built with his advisor during that time. He wants to give that same sense of autonomy to his advisees because that’s where “the magic happens” in research.

“After a Ph.D. student’s first year, I try to keep a safe distance from them,” said Agah. "They probably don't know why, but I want to give them a sense of ownership. They’re not doing it [the research] for me, they're doing it for themselves – and that’s when creativity kicks in.”

Yuhao Zhang, assistant professor, Center for Power Electronics Systems researcher

Yuhao Zhang is another researcher searching for ways to advance and improve current semiconductor technologies. He and three other researchers in ECE are working on optically driven versions of these devices. The goal is to improve efficiency and reduce the environmental impact of today’s power switches that are electrically driven. Zhang is hopeful that the research will make this multibillion dollar industry a little greener.

“The power semiconductor market has reached $40 billion and is forecasted to more than double that amount by the year 2030,” said Zhang. “Innovation in power semiconductors is a driver for energy savings in data centers, electric vehicles, and the electric grid. Therefore, it holds the key for realizing the unprecedented cuts in carbon dioxide for a greener and more sustainable environment.”

Learn more about semiconductors at Virginia Tech.