Research and industry partnership helps forge 21st century metallurgy

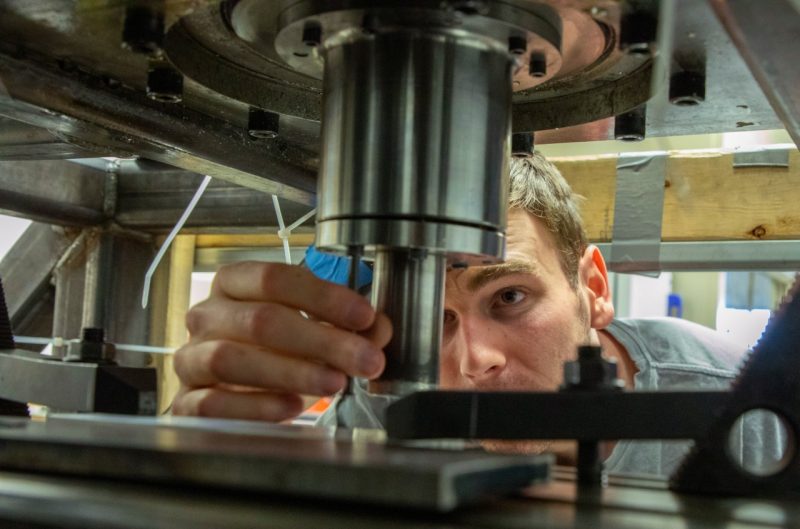

Hands-on research experience puts materials science and engineering senior Gideon Crawford at the forefront of additive manufacturing for defense and industry

At 12 years old, Gideon Crawford was making knives in the family basement, and now, as a Virginia Tech senior in the Department of Materials Science and Engineering, he’s helping forge the future of metallurgy.

Crawford is part of the Yu Research Group, led by Assistant Professor Hang Yu, whose lab partners with Christiansburg’s MELD Manufacturing Corp., at the leading edge of 3D printing metals for industry and national defense.

The technology, called additive friction stir deposition (AFSD), is relatively new, dating to the early 2000s, and students in Yu’s lab are helping develop this scalable, low-temperature process that could benefit a range of industries.

Through his work in the lab, Crawford is not just learning to prepare samples for analysis and write research summaries in his senior year, he’s stoking a passion and building a resume.

“During my tour of campus, my mom and I dropped in on Michelle Czamanske, the advisor for materials science and engineering, and she spent an hour talking to us about the program and all of the opportunities for undergraduate research here,” Crawford said. “This convinced me that I could grow and learn during my time as an undergraduate.”

The research experience in Yu’s lab may put him more in demand with employers and graduate programs, a major goal of the College of Engineering and the wider university.

AFSD constitutes a major step forward in additive manufacturing, Yu said. The forging-based additive process allows some of the size and shape advantages found in casting, while increasing strength and decreasing impurities. And there’s much left to explore from a research standpoint.

Yu discovered the MELD’s AFSD process after arriving at Virginia Tech in 2016, and today his lab is doing about $1.9 million in research on AFSD funded by the U.S. Department of Defense, the National Science Foundation, and Ford Motor Co.

He also is wrapping up work on the first major academic book on the subject, titled “Additive Friction Stir Deposition,” which is scheduled to be published on July 1 by Elsevier, a Netherlands-based company specializing in scientific, technical, and medical content.

“We think this is definitely going to have some big impact in areas where aluminum is important. The defense department uses a lot of high-strength aluminum, which is hard to repair,” Yu said. But AFSD repairs done in his lab “have good mechanical properties. We also explore other materials, like copper, steel, or even titanium.”

Traditional casting of these metals uses high heat to melt the material, which is then poured into molds to cool. With this approach, metals can be used to form a range of shapes and sizes. But the process can introduce impurities and compromise the strength of the finished product, Yu said. The act of forging heats metal and uses pressure to deform it without melting. While this process creates a stronger product with fewer impurities, the shapes and sizes of forged products are limited.

But MELD’s specially designed printers spin metal feedstocks at high speeds against substrates to heat them. The machine also exerts downward pressure and moves in various directions depending on the design being printed. Under these conditions, the metal flows without melting and can be deposited in strongly bonded layers to build seamless components in various shapes and sizes.

In MELD’s plant in Montgomery County’s Falling Branch Corporate Park, a 10-foot-diameter seamless aluminum cylinder hangs on the wall and hints, founder and CEO Nanci Hardwick said, at the untapped potential for her company’s technology.

“If you were to do this in a metal with a different technology, it wouldn't be flat. And this came off the printer table just like this,” Hardwick said. “So to make something this big with this much metal and have it still be flat — not misshapen from residual stresses from excess heat — is really significant.”

The number of potential applications also is exciting.

“It could be a fuel tank or spacecraft. It could be the structural body of the underwater vehicle like a submarine,” Hardwick said. “There are numerous parts of this size in large ships like aircraft carriers. So there are a number of cylinders of varying sizes that are used in all kinds of vehicles and products across industries.”

Normally those are made by traditional forging or casting, but right now, clients of that kind of manufacturing are experiencing long wait times for orders.

“So some of our customers are interested in this ability to make really large parts just because it will allow them to speed their construction schedule by one and two years,” Hardwick said.

MELD primarily builds and sells its printing machines to research institutions like Virginia Tech, government agencies like the Department of Defense, and a range of heavy industries, Hardwick said. In fact, the company is working with the Army to build a machine big enough to print tank components. It will be capable of printing parts up to 12 feet tall, making it one of the largest metal printers operating today.

To build its customer base, MELD relies on good research and development by partners, such as Yu’s lab, to prove the benefits of its technology.

“They're so critical for us because they have expertise. They have one of our machines, and they have world-class characterization equipment,” Hardwick said. “Because this is a new process, our customers need to know a lot of information about the material that we print, and Virginia Tech is helping us get that information.”

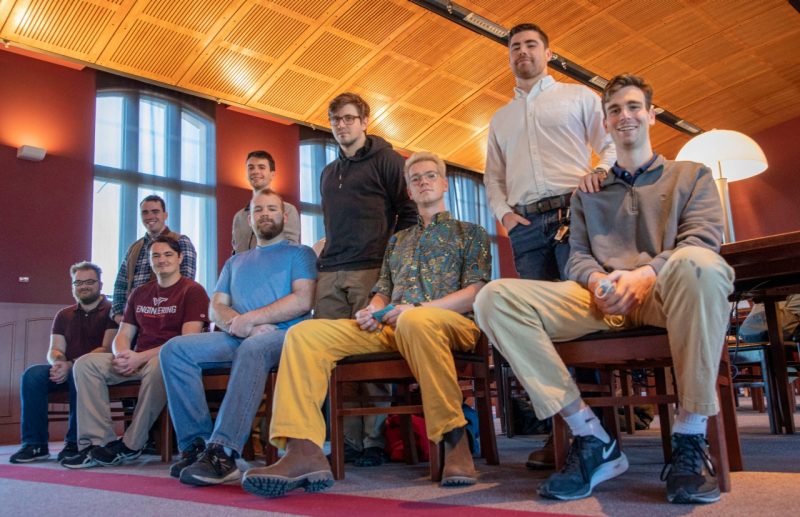

Doctoral candidate Jake Yoder has been a big part of that relationship over the past four years. In addition to his work in Yu’s lab, Yoder works part time at MELD to explore how AFSD might be used on high-value materials like titanium.

“There's fundamentally no restriction on which metals you can print,” Yoder said.

Furthermore, there’s so far no technical limit on how fast the process can print.

“I've personally seen aluminum run at 50 pounds an hour, which is very fast,” he said. “They haven't reached any technical limits on that number. I'm very excited to see how much further you can push it.”