Virginia Tech aircraft to participate in Malawi drone corridor test

A Virginia Tech mechanical engineering professor and his team have been invited by the United Nations Children’s Emergency Fund, UNICEF, to be among the first to use a new humanitarian drone testing corridor opened by the government of Malawi and the aid agency.

The team will test a new autonomous drone designed to fly to remote locations and collect dried blood samples for HIV testing.

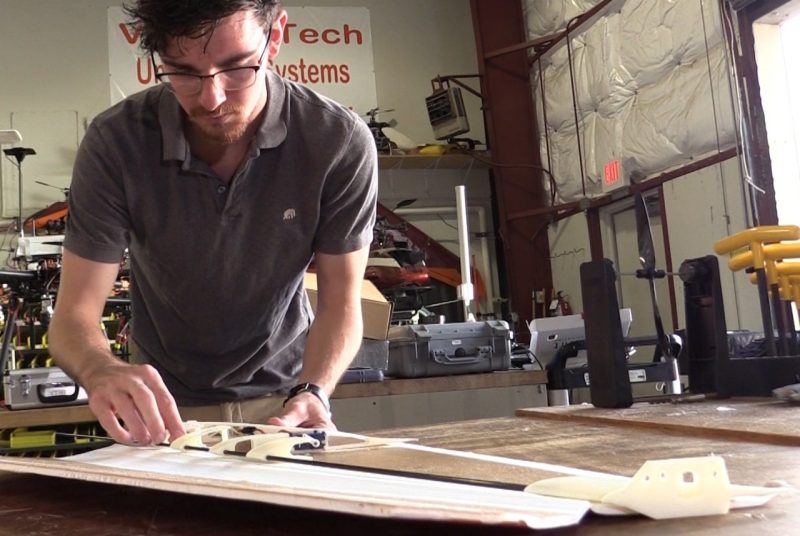

Kevin Kochersberger, an associate professor of mechanical engineering in the College of Engineering, is an advisor to senior design project teams working with hospitals and communities in Malawi. Kochersberger and several of his students will travel to Malawi Nov. 4-12 and test EcoSoar, a drone designed and built by his Unmanned Systems Laboratory.

EcoSoar was originally developed for a company called Management Systems International to monitor canals in Afghanistan. Kochersberger was invited by UNICEF to bring the system to Malawi as part of their corridor test trials.

“The main concern for UNICEF is to have an aircraft that can quickly and efficiently go to a remote community and collect dried blood samples to be tested for HIV,” Kochersberger said.

With a small cargo compartment capable of holding a stack of blood sample cards, the aircraft can be easily loaded, and launched from the remote location to return autonomously to its point of origin. An 8-megapixel camera in the aircraft’s fuselage is also of interest to UNICEF as a way to aid in disaster relief during floods or other catastrophic events.

“Many of the aircraft being brought in for testing in the corridor are expensive machines that cannot be repaired on site. Africa is a challenging environment, and local support is critical to success,” explained Kochersberger.

The EcoSoar aircraft is inexpensive at around $350 to $500 and designed to be built by local craftsmen in Malawi who will be trained in the process Kochersberger and his team have developed.

After 3-D printing internal components, the flying wing design can be made from scratch in a few hours using easily sourced material such as foam core poster board and hot glue. The rugged design includes sensors and components embedded into the body of the aircraft.

Written by Rosaire Bushey