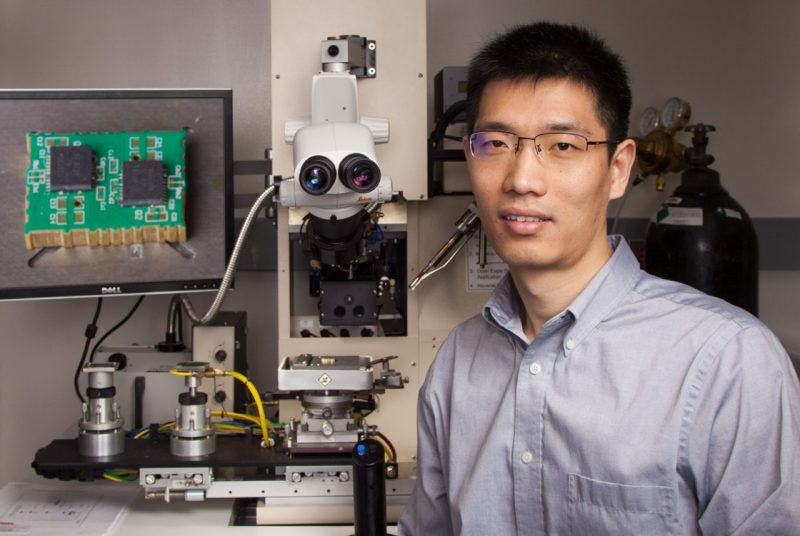

Virginia Tech’s Qiang Li works to improve battery life in small electronic devices

In a world with innumerable small electronic devices, battery life has become a major concern. We often grumble about how often we need to recharge our smartphones, wearable devices, and remote sensors. Today’s voltage regulators can be power hogs and are not able to respond quickly enough to meet the widely varying demands of a microprocessor with maximum efficiency.

Qiang Li, an assistant professor in Virginia Tech’s Bradley Department of Electrical and Computer Engineering, is solving this problem by reinventing the voltage regulator—a device that typically ferries power to microprocessors.

The dream voltage regulator can deliver varying, or dynamic voltage levels as needed by the microprocessor. At 20-50 MHz, it has a frequency more than 10 times higher than traditional converters. The proposed voltage regulator can dramatically reduce microprocessor power consumption to increase battery life by 50 percent or more.

Li, who specializes in power electronics, was awarded the National Science Foundation Faculty Early Career Development (CAREER) Award for this effort. The CAREER grant is one of the NSF’s most prestigious awards, given to junior faculty members who are expected to become academic leaders in their fields.

Li must solve many issues in his quest. The first is location on the chip. The impedance between the voltage regulator and the microprocessor prevents conventional voltage regulators from responding quickly. If the voltage regulators can be placed close to the microprocessor, he says, the system could support the desired dynamic voltage and frequency scaling.

Getting close to the microprocessor is difficult, however. Today’s voltage regulators contain passive components, such as inductors and capacitors, that are bulky and occupy a considerable footprint on the motherboard, explained Li.

His solution is to save space by integrating multiple inductors into a single-piece magnetic core, using a lateral flux inductor structure. This structure will allow the voltage regulator to achieve low-profile, high-density, low-winding-resistance, and confined flux at the same time.

“It’s a very effective power consumption reduction technique for microprocessors,” said Li.

In seeking a smaller footprint and greater proximity to the microprocessor, Li is also exploring 3-D integration methods, such as printed circuit board embedding and 3-D printing. He is collaborating with interdisciplinary researchers within the university and in industry to discover options.

But a shorter power delivery path and smaller footprint are not enough: the frequency must also increase. Li’s goal is 10 times higher. This is achievable, he says, but it may cause increased thermal stress, switching losses, and electromagnetic interference.

The complex tradeoffs must be managed for efficiency and reliability, but achieving dynamic voltage and frequency scaling is a challenge worth undertaking, Li said. “It’s a high-risk, high-return project.”

The project's education component will incorporate high-frequency power converter design into the department’s curriculum and offer professional development opportunities for power electronics industry engineers via short courses.

Li is also collaborating with the Center for the Enhancement of Engineering Diversity to provide opportunities for K-12 students and underrepresented groups to learn about technologies typically only worked on by people with advanced degrees in power electronics.

Written by Kelly Izlar