Polymer coating could be breakthrough in diagnostic technology

When physics professor Randy Heflin brought his 18-month-old daughter to the pediatrician, he didn’t know the visit would provide the motivation for a discovery that could herald a breakthrough in diagnostic technology. He just knew his daughter was ill – and that it would take three days to confirm what the doctor believed.

“It turns out my daughter had a MRSA infection,” (methicillin-resistant Staphylococcus aureus) Heflin said. “Our pediatrician was very pro-active and didn’t wait until the lab test came back. She knew what it was and, with our concurrence, started treatment right away.”

The treatment most often given to MRSA patients involves specialized antibiotics for which the bacteria have not yet developed resistance. Medical professionals, however, don’t like using antibiotics in general and the most advanced ones in particular unless they’re sure of what they’re up against. “It (MRSA) is a very serious issue to the medical community because if the bacteria build a resistance to current antibiotics, there will be major health crisis. We aren’t coming up with new antibiotics as fast as the bacteria are building immunities,” Heflin explained.

His daughter, after being given several different treatments and a three-day hospital stay, recovered and Heflin went back to his lab working with self-assembling polymers, which consistently build themselves into very thin layers of nanometer thickness on a variety of surfaces, including silicon chips and microscope slides.

“There was a graduate student, Zhiyong Wang, who had gone off to a corporate lab after getting his master's degree at Virginia Tech, and when he came back after a few years for his doctorate he approached me about some research he had done with optical fibers. We quickly discovered that we could get huge changes in the transmission of light through the fiber when we deposited our self-assembled polymers on the fiber surface,” he said.

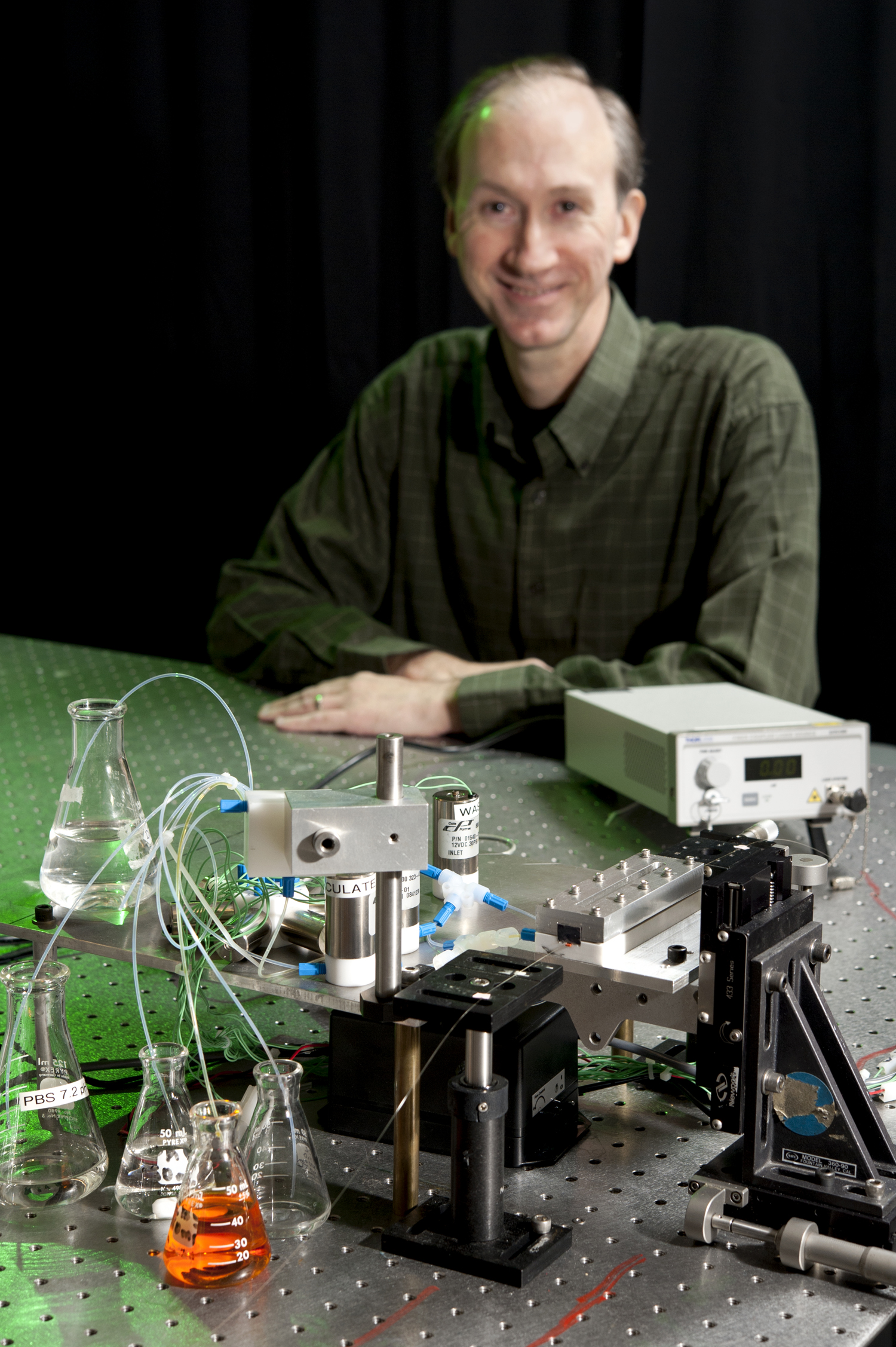

Initially, the work was focused on telecommunications applications, but Heflin and his collaborators Professor Tom Inzana and Dr. Abey Bandara from the Virginia-Maryland Regional College of Veterinary Medicine, and Ziwei Zuo of Xuzhou, China, a physics graduate student, soon realized that coating the fiber with the self-assembling polymer layers and then adding a receptor layer to specifically bind the MRSA bacteria, had the potential to revolutionize the diagnosis of MRSA, and, potentially, many other diseases with the appropriate receptors.

“An optical fiber consists of two parts,” Heflin explained. “The fiber itself is about 120 microns in diameter and the core, where light stays confined, is about 10 microns. The total internal reflection in that inner area keeps the light confined in the core over long distances, which makes it so useful for communications and other applications. Using the polymer coatings, we’re able to couple the light out of the core and into the cladding (outer part) of the fiber in an amount that is proportional to the number of MRSA bacteria bound to the receptor on the surface of the fiber."

Many people have worked with fibers in an effort to detect biological organisms, but it requires very high sensitivity to be useful. In addition, the fibers must detect only a specific organism and have the ability to filter our any other biological ‘noise’ that may be present.

“We can take a fiber and soak it in an aqueous solution of charged polymers which will adsorb onto the surface of the fiber in about three minutes,” Heflin said. “The idea then is to soak a swab from a patient into a solution, put the solution on a fiber with the polymer coating and the receptor to detect MRSA. In less than an hour, you’ll have an indicator of whether or not the bacteria is present.”

Heflin said he expects the test to cost anywhere from $50 to $100 – about the cost hospitals currently get charged to have their samples tested at a lab.

“The difference is,” Heflin explained, “that our test takes less than an hour. Sending it off to a lab for the traditional culture test typically takes about three days. That’s three days of a patient waiting; three days of potential hospitalization; or worse, three days of either being on antibiotics that are unnecessary or not being on the advanced antibiotics that are necessary.”

Heflin co-founded the company Virginia nanoTech with Michael Miller and Jimmy Ritter, and they have received small business funding from the National Science Foundation to commercialize this diagnostic technology. They say they expect to have a prototype working at the Carilion Clinic in Roanoke within the next 12 months and hopefully have an approved design ready to go within a couple years after that.

“The prototype won’t be used for diagnosis because it hasn’t been FDA-approved yet,” Heflin explained. “It will be used to show how its results match to lab-based diagnostics.”

The team is confident their polymer-coated fibers will provide the needed sensitivity and specificity for rapid, accurate diagnosis.

Heflin is confident that anyone who brings their child to the doctor will appreciate getting results while they are there and not having to wait three days for a lab test.