Center for Photonics Technology receives two $1 million awards

Looking for novel sensing technologies that will aid in everything from clean energy technology to the monitoring of various gases, the U.S. Department of Energy (DOE) and the Electric Power Research Institute (EPRI) have selected Virginia Tech's Center for Photonics Technology to lead efforts in three unique projects. Jointly, the awards are valued at more than $3.2 million.

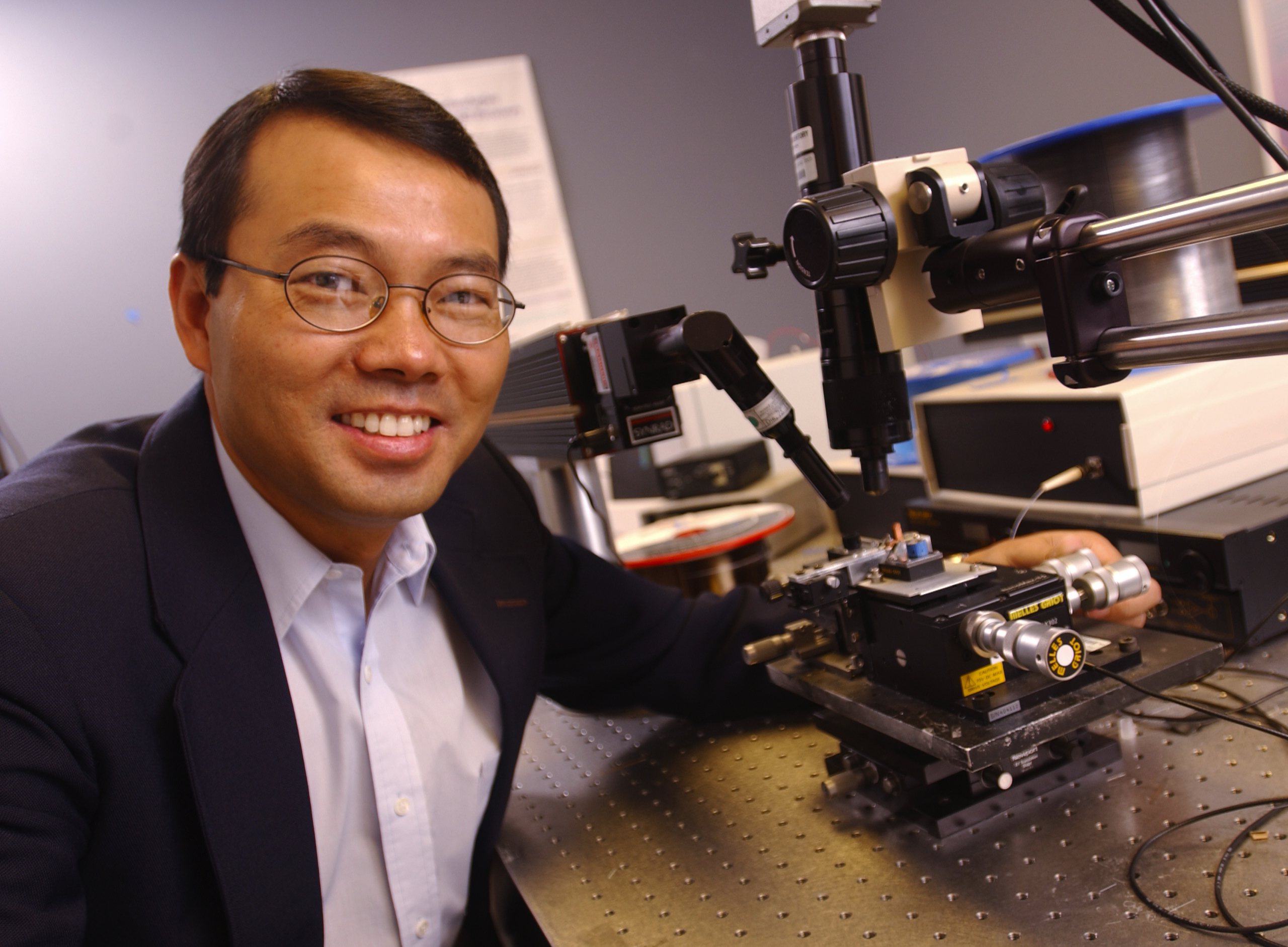

The center has a history of achievements in the area of optical fiber sensors. Anbo Wang, Virginia Tech's Clayton Ayre Professor of Electrical Engineering and director of the center, holds a number of patents on different sensing technologies.

In the 1980s, Wang developed a sensor technology for remote oil storage measurement with a high long-term accuracy. In the 1990s, he developed another fiber-optic sensor technology for oil applications, which earned him a prestigious Research and Development 100 Award in 2004.

As the research grew, Wang started the center in 1997, and it conducts a wide range of research in fiber optics for sensing, communications, and biophotonics. Creating new and improved sensors for harsh environments is a continual focus of the photonics center.

One of his DOE latest awards is critical to the development of clean energy technology in America, according to the government agency.

This new award requires Wang's center to work on the creation of a first-of-a-kind, high temperature distributed sensing platform and on improvements to the operations of fossil energy power plants. The Virginia Tech center is one of three selected by the DOE to develop these novel sensing and control technologies aimed at insuring the efficient operation of advanced, zero-emission power systems and the improvement of operations at existing fossil energy power plants.

The DOE is asking Virginia Tech to develop a first-of-a-kind technology for remote fiber optic generation and the detection of acoustic waves for structural health monitoring. The envisioned technology would require no electric power supply at the monitoring site and at the detected acoustic signature, as well as the additional returned optical signal. It would allow the recording of information about multiple material conditions including temperature, strain, corrosion, and cracking.

This project will last 36 months, and DOE funding will total $1,195,770.

In the second DOE project, Wang and his colleagues will develop a unique sensing platform to monitor the varying space and time properties of a gasifier's refractory wall.

In a gasifier, a carbon-based material such as coal or petroleum can be converted at a high temperature into a gas, including hydrogen, carbon monoxide, or a synthetic gas. The temperatures may exceed 1,000 degrees Celsius. The term refractory refers to the materials that are used to line the walls of the gasifiers, protecting the shell of the gasification chamber from the very intense gasification process.

Wang's sensors will be used to identify problem areas such as localized hot spots in the liner of the gasifier.

Wang is working with Eastman Chemical Co., to develop a baseline requirement matrix for refractory health monitoring to guide the design and fabrication of the new sensor. Together, they will actually build a laboratory-scale double-layer refractory furnace to demonstrate the distribution of high temperatures between the two layers and prove the sensor's capability to accurately detect hot spots, Wang said.

Finally, the Electric Power Research Institute is funding a new four-year study, asking the photonics center to investigate the validity of two approaches to monitoring and detecting hydrogen and acetylene. The use of fiber optic sensors for on-line detection of gas in transformers is useful because they have an "inherent immunity to electromagnetic interference, high sensitivity, light weight, and small size," Wang said.

Power transformers are the most critical and costly component in electric power transmission and distribution systems. Catastrophic failures of transformers can occur without warning, resulting in serious oil spills, fires, extensive damage to adjacent equipment and major disruption to power service. When the transformer can not be repaired due to the extensive damage, the cost of the failures can be several times the cost of new transformers since the costs for reinstallation, transportation, other equipment damage and/or outages caused by the failure, and lost sales revenue, can easily drive the total cost of a single failure into the tens of millions of dollars, Wang explained.

Transformer failures are often caused by dielectric breakdowns that can be triggered by a surge in various chemical gases such as acetylene and hydrogen dissolved in the transformer oil. Dissolved gas detection is thus an important method to learn the health condition of a transformer. The detection is currently handled manually by a process called Dissolved Gas Analysis (DGA) which is a routine procedure in the power industry. However, DGA is an expensive method involving oil sampling, shipping, and laboratory analysis. It often takes days for the measurement results to be obtained. Although DGA can be installed on site and access the transformer oil with a connection port, the cost is still high.

In this project, Virginia Tech will develop a more economical method for on-line dissolved gas detection. The key is that this method does not require oil sampling and provides real-time data about transformer health.